PA-3.0 SCADA-5.0 control panel

with monoblock

6 176 072 ₸

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| Software on your own SCADA system complete with a monoblock: accounting for the consumption of materials and equipment operation, remote access and control over the work in the local network |

| Automatic operation by pressing "one" button |

| Recipe storage database for concrete production |

| Programmable Logic Controller |

| Сontrol panel case protection - IP54 |

| Power cabinet case protection - IP54 |

| Control, protective and switching equipment "Omron", "Siemens" |

| Set of diagrams and instruction manual |

| Touch control panel, diagonal 10 inches, wide viewing angle, TFT-screen, 65,000 colors. |

| Manual control panel with ingress protection buttons on mimic panel |

| Tablet for controlling a concrete plant |

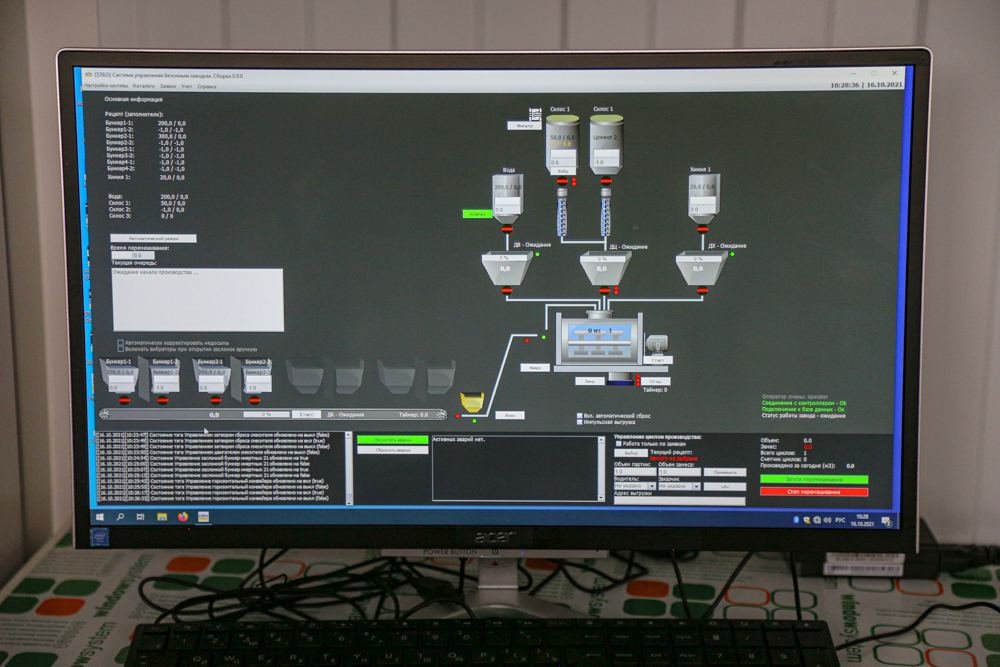

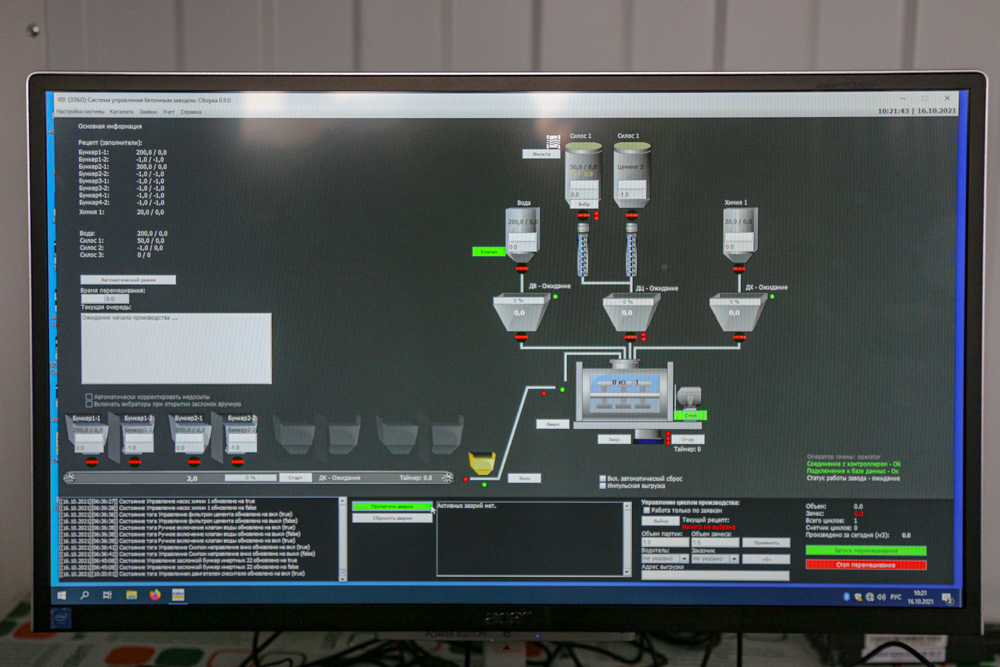

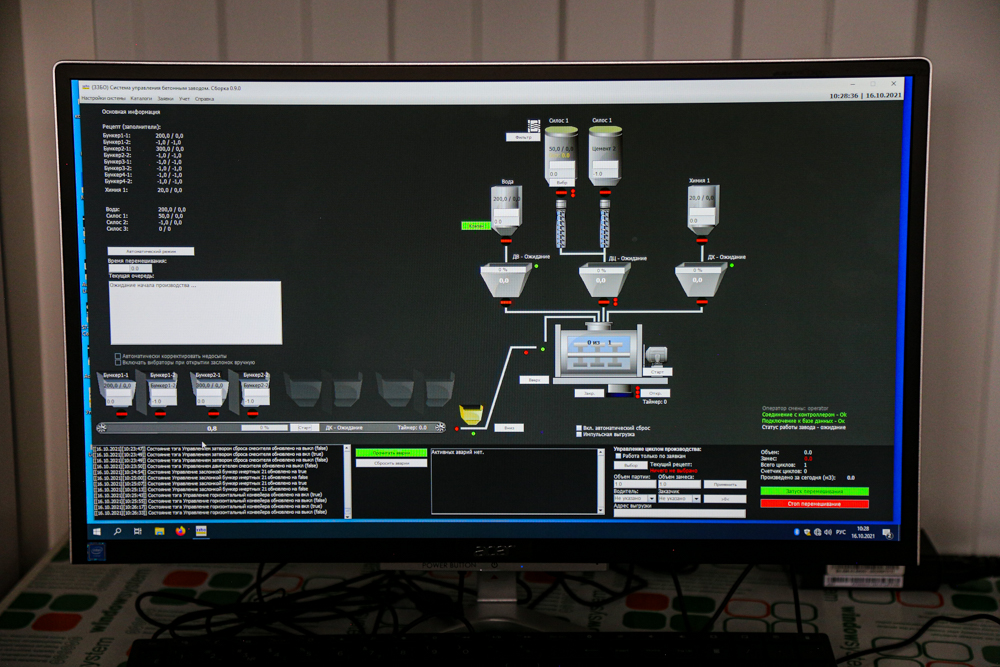

С помощью системы автоматизации «ПА 3.0» можно управлять бетонным заводом, в ручном и полуавтоматическом режиме работы, используемых для отладки оборудования и отработки рецептов выпускаемой продукции. А также в автоматическом режиме по принципу «одна кнопка», позволяющем получить заданное количество бетона, по выбранному из памяти рецепту и предустановленным параметрам работы оборудования. Расширенные настройки каждого отдельного узла, помогают подстроить работу завода под необходимый технологический процесс производства и добиться максимальной производительности в конкретных условиях производства и перестроить цикл за пару минут. Парольная защита разных уровней доступа и функция создания ежедневного отчета на USB накопитель в базовой комплектации.

Широкий перечень подключаемого оборудования, позволяет подавить к используемому оборудованию новое, например вторую линию подачи цемента (силос, шнек), конвейер для выгрузки бетона, разделить работу дозирующего комплекса до 6 видов заполнителей и т.д. Весь функционал, подробно расписан в руководстве по эксплуатации. Своевременное отображение на панели оператора предупреждений о нештатных и аварийных ситуациях, позволяет оперативно выявлять и устранять их.

The basic package in 2018 the option: control to achieve homogeneity of the mixture and its mobility.

The control system is easy to operate thanks to the monoblock 21.5 inches. For production, you must select the recipe and the amount of concrete.

The PA control panel is designed to control the concrete plant in the following modes:

- Manual mode. Operation with graphical control panel with intuitive panel and display of operation on touch graphical panel

- Auto. Operation with a graphical touch terminal. The operator needs to select the recipe and the amount of concrete required, press the “CYCLE” button

- Automatic (optional). Work using a personal computer (monoblock) installed on the control panel. Selection (task) of the required recipe and the required number of batches. In addition to the required technological information, the computer screen displays: - messages about malfunctions and errors of the control system - information necessary to account for the consumption of materials (water, cement, electricity, chemical additives) and finished products. Information can be issued for any period of time - year, month, week, day. – information necessary to control the work of personnel (fixing actions, error control, entering incorrect recipes)

- Remote (optional mode). Using a personal computer (monoblock) connected to the Internet and located anywhere in the world

- Automatic mode according to the principle "one button"

- Monoblock with software

- Localization for foreign languages is possible

- Detailed graphic mnemonic diagram of concrete plant units

- achieve homogeneity of the mixture control system

- Status monitoring, error display

- Automatic event recording

- Preparation of invoices, the ability to print reports

- Remote monitoring of RBU via Ethernet network

- Automatic sending of reports by e-mail

- Possibility of administration

- Remote access to reporting and system distribution

Technical Features

- Power supply 3-phase with neutral to earth, in 400

- The degree of protection against dust and moisture IP54

- achieve homogeneity of the mixture control system there is

- Work transfer coefficient of strain gauges (RCP), mV / V 3 (2)

- The input analog signal "current loop" controller mA 4...20

- The maximum total error of measurement of weight,% 0,1

- Water dispenser control voltage, chem. additives, cement and mixer gate, V 24 DC

- DC damper control voltage, V 220 AC

- Weight, kg 90

- Height, mm 1,000

- Width, mm 650

- Depth mm 285

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2026

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

г. Astana, prospekt Akžol, Zdanie 44, of. 32

e-mail: sales@zzbo.kz

Artem Kononovich

Director of the branch in Kazakhstan

Phone: +7 (7172) 760-141

e-mail: sales@zzbo.kz

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions