Dosing complex DKM-120

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| Inert inert bunkers BI-120 (4 x 30) - 8 sections. Total volume 120 cubic meters. meters |

| Preparation under registers installation for heating inert materials |

| Pneumatic equipment - 8 electric pneumatic distributors, a set of fittings and tubes, 8 quick exhaust valves, 1 pneumatic regulator, a filter with a pressure gauge |

| Вибратор MVE 300/3 - 10 шт. |

| Dispenser inert CI-12 (conveyor) with the lined drive drum. Drive power 18,5 kW |

| Ролики с антикоррозийным покрытием |

| Strain gauges - 6 pcs. |

| CAS connecting box |

| Signal amplifier - weight sensor |

| Passport to complex metering and purchased products |

| ABAC Pole Position L20P Compressor (Italy) |

| Service platforms with stairs |

| Subframe for installation at height |

| Automatic control panel |

| Grating on the hopper |

| Registers for heating |

| Caps for bunker |

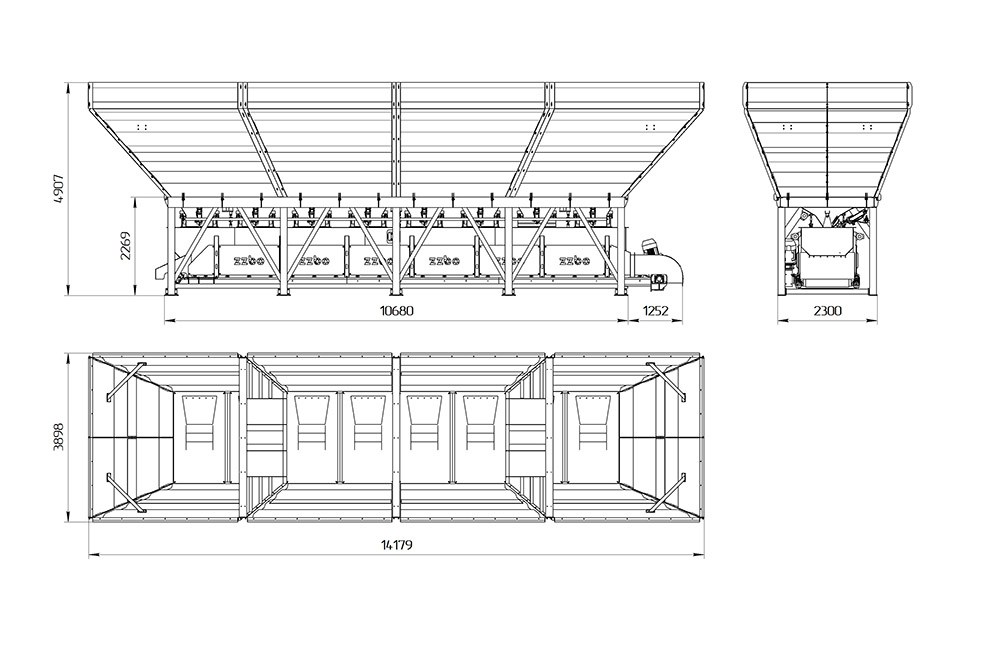

Dosing complex DKM-120 for storing inert materials, consists of 4 bins, the total volume of four 120 meters³.

Each silo volume 30 m³ has two unloading gates for a more uniform distribution of inert materials along the conveyor and more accurate dosing.

Width, mm bunker loading – 3 400 mm.

The shutter is controlled using a pneumatic cylinder installed on it. Due to the use of two shutters: it is possible to achieve high precision. Vibrator-shakers MVE 300/3 are installed on each bunker – всего 8 штук.

To ensure the performance of the metering complex it must be connected to a compressed air line with a working pressure of not less than 0,6...0,8 mPa.

Дозатор инертных (тензометрический конвейер) установлен под бункерами на шести высокоточных тензодатчиках общей грузоподъемностью 18 тонн. Конвейер снабжен устройством для плавного пуска (частотный преобразователь). На конвейере установлено 2 вибратора.

Inert materials (sand, screenings, crushed stone, etc.) are fed into bunkers using front-end loaders or other loading mechanisms. To protect against large fractions getting into the bunkers, gratings with a cell of 100 mm x 100 mm or other sizes (optional) can be installed on the bunkers.

Principle of operation

Inert materials are distributed among the compartments of the dosing complex and are kept there until required. The process of dosing inert materials is carried out according to a given recipe.

The automatic control system sends a signal to open the sector gate, after which inert materials from one of the hoppers are poured onto a strain gauge conveyor. After reaching the specified weight on the conveyor, the valve will automatically close. For more accurate dosing, a pulse opening mode is possible, in which the shutter makes several openings/closings in a short period of time.

The process is then repeated with the next hopper until all materials, in accordance with the recipe, are on the strain gauge conveyor. To prevent caking of inert materials, vibration motors are used in the design of the dosing complex.

After the cycle is completed, the dosed materials are unloaded and the dosing cycle is repeated.

Can be supplied in a protective coating of zinc. The coating is applied by cold galvanizing.

- Total volume 120 cubic meters. meters

- 4 bunkers, 30 cubic meters each

- Perevozitsya in 1 evrofure

- Bin loading width 3.4 meters

- Accurate dosing - accuracy better than ± 1%

- Hopper walls made of bent profile, metal 6 mm thick

Technical Features

- Total volume of bunkers, m³ 120

- Volume of one bunker, m³ 30

- Vibrator power, kW 4

- Batching error,% ±1

- Belt speed, m/s 1,4

- The pressure in the pneumatic system, MPa 0,6...0,8

- Aggregate size, mm max 70

- Power Supply, 380

- The maximum dose weighing kg 9,000

- Total installed power, kW 21

- Weight kg, no more 16500

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2026

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

г. Astana, prospekt Akžol, Zdanie 44, of. 32

e-mail: sales@zzbo.kz

Artem Kononovich

Director of the branch in Kazakhstan

Phone: +7 (7172) 760-141

e-mail: sales@zzbo.kz

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions