asphalt plants

Showing all 34 results

- Mobile asphalt plants

- Stationary asphalt plants

- Filtration plants

- Options for ABZ

- Basic equipment BMZ-80

22 500 016 ₸

- Productivity, t / h 100

- Lifting height, m 14

- Number of buckets, pcs 70

- Bucket pitch, mm 400

- Bucket volume, l 8

- Electric motor power, kW 11

- Rotation frequency of the drive shaft, rpm 52

85 626 128 ₸

- Productivity, tons hour 20

- Количество и объем бункеров, кол-во х м. куб 3 x 8

- Weighing range of inert, kg 2,000

- Asphalt-shaft, l 750

- Total electric power of the plant, kW 110

- Smoke exhauster power, kW 15

- The volume of the hopper ready asphalt, tons 8

229 205 535 ₸

- plant performance 80 t / h (3% moisture material)

- Supply hopper with inert materials, count and volume. 5 bins of 8 m3

- The thermal power of the burner 6500 kW

- Number screening sieves 5

- The volume of hot material hopper 14 м³

- Weight one batch 1,000 kg

- Total electric power of the plant, kW 230

13 251 168 ₸

- Filtration plants 1,200

- Filtration plants 3,000

- Filtration plants 14

- Number of tiers of screening surfaces, pcs 5

- Number of tiers of screening surfaces, pcs Number of tiers of screening surfaces, pcs

- Number of tiers of screening surfaces, pcs Number of tiers of screening surfaces, pcs 1,000

- Number of tiers of screening surfaces, pcs 100

15 166 480 ₸

- Number of tiers of screening surfaces, pcs3 14

- Number of pneumatic cylinders, pcs. 5

- Number of pneumatic cylinders, pcs.3 7

- Number of pneumatic cylinders, pcs.3 Number of pneumatic cylinders, pcs.

- Number of pneumatic cylinders, pcs.3 1,6

- Number of pneumatic cylinders, pcs.3 1,6

- Number of pneumatic cylinders, pcs.3 2,1

30 252 992 ₸

- Number of pneumatic cylinders, pcs. 1,000

- The volume of the batcher of hot inert materials, m3 The volume of the batcher of hot inert materials, m

- The volume of the batcher of hot inert materials, m3 0The volume of the batcher of hot inert materials, m

- The volume of the batcher of hot inert materials, m3 0,35

- The volume of the batcher of hot inert materials, m The volume of the batcher of hot inert materials, m

- Load cells for weighing mineral powder and dust, pcs x kg Load cells for weighing mineral powder and dust, pcs x kg

- The volume of the batcher of hot inert materials, m Load cells for weighing mineral powder and dust, pcs x kg

7 193 984 ₸

- Drive power, kW 7.5

- Load cells for weighing mineral powder and dust, pcs x kg 75

- Load cells for weighing mineral powder and dust, pcs x kg 1,5

- Load cells for weighing mineral powder and dust, pcs x kg 600

- Load cells for weighing mineral powder and dust, pcs x kg O Load cells for weighing mineral powder and dust, pcs x kg

32 628 512 ₸

- End product capacity, t/h 80

- End product capacity, t/h 3

- End product capacity, t/h 7.5

- End product capacity, t/h 4

- Load cells for weighing mineral powder and dust, pcs x kg 11

- End product capacity, t/h End product capacity, t/h

- Operating thermal power of the burner, MW Operating thermal power of the burner, MW

5 051 312 ₸

- Operating thermal power of the burner, MW3 8

- Operating thermal power of the burner, MW 2,2

- Operating thermal power of the burner, MW Operating thermal power of the burner, MW

- Operating thermal power of the burner, MW 500

- Vibrator power, kW 0Vibrator power, kW

6 664 000 ₸

- Length, mm Maximum productivity of the belt feeder, t/h

- Width, mm Maximum productivity of the belt feeder, t/h

- Height, mm Maximum productivity of the belt feeder, t/h

- Weight, t 2,7

9 270 016 ₸

- Maximum productivity of the belt feeder, t/h Maximum productivity of the belt feeder, t/h

- A type Maximum productivity of the belt feeder, t/h

- Construction type Construction type

- Construction type 85

- Construction type3 1,500

- Construction type O from “Bulgaria" 200

- Productivity (at a flow rate in the cylindrical part of 2.5 m/s), mOProductivity (at a flow rate in the cylindrical part of 2.5 m/s), m Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m

10 105 760 ₸

- A type Скруббер "Вентури"

- Construction type 96

- Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m3Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m

- Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m3Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m 30

- Supply Pump Parameters:

- Supply Pump Parameters: 4

- Supply Pump Parameters:3Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m Supply Pump Parameters:

37 367 792 ₸

- Filtration area, m² 430

- Supply Pump Parameters:3Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m Supply Pump Parameters:

- Supply Pump Parameters: 384

- Filter cloth material for sleeves Filter cloth material for sleeves

- Filter cloth material for sleeves O from “Bulgaria" Filter cloth material for sleeves

- Filter cloth material for sleeves O from “Bulgaria" Filter cloth material for sleeves

- Number of cleaning mechanisms, pcs 3

5 433 120 ₸

- Filter cloth material for sleeves3 1,57

- Dispenser volume, dm3 23

- Dispenser volume, dm3Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m Dispenser volume, dm

- Dispenser volume, dm 90

- Dispenser volume, dm Dispenser volume, dm

- Dispenser volume, dm Dispenser volume, dm

- Dispenser volume, dm Dispenser volume, dm

576 880 264 ₸

533 030 622 ₸

- Plant productivity, t/h 160 (3% moisture content of materials)

- Feed hoppers with inert materials, quantity, volume 6 bunkers of 10m³

- Thermal power of the burner, MW 14

- Number of screen sieves, pcs 6

- Hot materials hopper volume, m³ 22

- Weight of one batch, kg 2,000

- Dryer drum drive power, m² 4 x 11

7 164 976 ₸

- Productivity, m3Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m Productivity, m

- Productivity, m Productivity, m

- Drive power, kW 55

- Productivity, m 1450

- Productivity, m 16

95 321 333 ₸

- Производительность плавления битума, т/ч 6

- Суточная производительность по плавлению битума, м.куб/сут до 120

- Производительность по отгрузки битума, м.куб/ч 25-30

- Установленная мощность электропотребления не более, кВт 40

- Установленная тепловая мощность, кВт 500

- Расход природного газа, нм.куб/ч 69

- Давление подключения природного газа, кПа 4-36

7 465 248 ₸

- Productivity, m 2

- Productivity, m 2

- Productivity, m Side, top

- Side, top

- Side, top2 44

- Side, top2 10

- Upper tier, m2 34

9 701 216 ₸

- Productivity, m 1

- Reject hopper capacity (at a density of 1.8 t/m³), m³ (t) 0,1

- Installed power, kW 120

- 23 866 $ Reject hopper capacity (at a density of 1.8 t/m³), m³ (t)

- Reject hopper capacity (at a density of 1.8 t/m³), m³ (t) Reject hopper capacity (at a density of 1.8 t/m³), m³ (t)

- Maximum oil heating temperature, °C 23 866 $

-

The volume of the coolant m3

38 959 312 ₸

- Side, top Side, top

- Side, top Side, top

- Skip capacity (at a density of 1.8 t/m³), m³ (t) 0Skip capacity (at a density of 1.8 t/m³), m³ (t)

- Skip capacity (at a density of 1.8 t/m³), m³ (t) Skip capacity (at a density of 1.8 t/m³), m³ (t)

- Skip capacity (at a density of 1.8 t/m³), m³ (t) 1,3

- Skip capacity (at a density of 1.8 t/m³), m³ (t) 2

- Reject hopper capacity (at a density of 1.8 t/m³), m³ (t) Reject hopper capacity (at a density of 1.8 t/m³), m³ (t)

37 124 752 ₸

- Number of sections, pcs 3

- Total capacity (at a density of 1.8 t/m³), m³ (t) 28 (50)

- The capacity of the sections of the finished mixture (at a density of 1.8 t/m³), m³ (t) 12 (21.5)

- The capacity of the marriage section (at a density of 1.8 t/m³), m³ (t) 4 (7)

27 440 784 ₸

- Heat production of the boiler, Gcal/h; 00.3

- Bitumen pump performance, cube m; 15,7

- Maximum oil temperature, ° C +300/+250

- Operation temperature +5 ...+40 ° C

- Useful volume of bitumen storage, cube. m 28

- The volume of the coolant in the installation, cube. m 0,7

- Thermal insulation URSA basalt, mm 50

9 164 176 ₸

- Useful volume of container, m3 30

- Nominal capacity volume, m3 31

- Oil registers, quantity, pcs 2

- Coolant volume in registers, l 250

- Ventilation system hatch ⌀600 mm and round deflector DN = 250 mm

- Thermal insulation URSA basalt, mm Reject hopper capacity (at a density of 1.8 t/m³), m³ (t)

- housing material steel St.09G2S sheet, s=4 mm of the shell, s=6 mm of the bottom

15 654 128 ₸

- Useful volume of container, m3 45

- Nominal capacity volume, m3 48

- Heating area, m2 30

- Oil registers, quantity, pcs 2

- Coolant volume in registers, l 350

- Ventilation system hatch ⌀600 mm and round deflector DN = 250 mm

- Thermal insulation URSA basalt, mm 100

32 482 688 ₸

- Vibrator power, kW 5

- Vibrator power, kW 8

- Vibrator power, kW 2,2

- Vibrator power, kW 500

- Maximum productivity of the belt feeder, t/h Operating thermal power of the burner, MW

- Maximum productivity of the belt feeder, t/h 0Vibrator power, kW

- Maximum productivity of the belt feeder, t/h 7.5

29 341 984 ₸

- Power supply 3-phase with neutral to earth, in 400

- The degree of protection against dust and moisture IP54

- Work transfer coefficient of strain gauges (RCP), mV / V 3 (2)

- The input analog signal "current loop" controller mA 4...20

- The maximum total error of measurement of weight,% 0,1

- Напряжение управления дозаторами битума, пыли, инертными и затвором смесителя, В 220

- Weight, kg 180

36 996 960 ₸

- Oil heating mode, supply / return, max, Oil heating mode, supply / return, max,

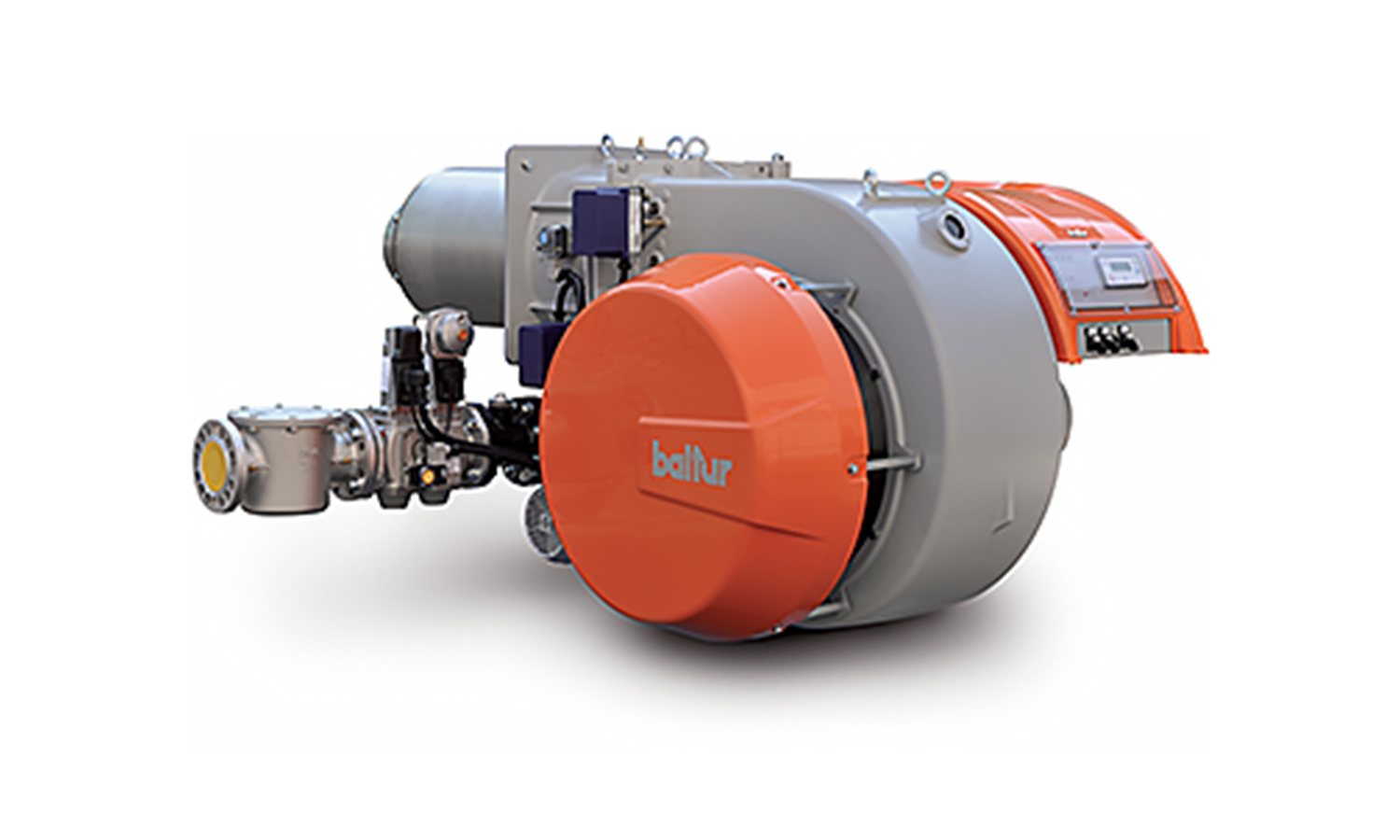

- Maximum thermal power (methane), kW 8,000

- Maximum thermal power (methane), kW 800

- Maximum thermal power (methane), kW 700

- Maximum thermal power (methane), kW 5

- Maximum thermal power (diesel), kW 8,000

- Maximum thermal power (diesel), kW 2,000

15 308 384 ₸

- Oil heating mode, supply / return, max, Oil heating mode, supply / return, max,

- Maximum thermal power (methane), kW 7000

- Maximum thermal power (methane), kW 1,000

- Maximum thermal power (methane), kW 500

- Maximum thermal power (methane), kW 5

- Maximum thermal power (diesel), kW 18,5

- Maximum thermal power (diesel), kW 22

11 852 512 ₸

- Thermal system, Gcal/time, MW/time 0,3(0,348)

- Efficiency, % not less 90

- The area of the heat exchanger, m2 16

- The volume of the coolant, m3 0,35

- Installed power, kW 8.5

- Power Power 3F, V/Hz Reject hopper capacity (at a density of 1.8 t/m³), m³ (t)

- Oil heating mode, feed/return, ° C 300/250

14 252 336 ₸

- Thermal system, Gcal/time, MW/time 0,46(0,54)

- Efficiency, % not less 90

- The area of the heat exchanger, m2 20

- The volume of the coolant, m3 0,4

- Installed power, kW 9

- Power Power 3F, V/Hz Reject hopper capacity (at a density of 1.8 t/m³), m³ (t)

- Oil heating mode, feed/return, ° C 300/250

4 860 016 ₸

- Capacity, tons max 32

- Capacity, cu m 22

- Weight, kg 2290

- Tank diameter, mm 2300

- Height, mm 8,432

- Loading pipe diameter, mm 102

- MVE300 Vibrator, kW (optional) 00.3

6 994 848 ₸

- Capacity, tons max 52

- Capacity, cu m 35

- Weight, kg 3020

- Tank diameter, mm 2300

- Height, mm 11,332

- Loading pipe diameter, mm 102

- MVE300 Vibrator, kW (optional) 00.3

15 931 664 ₸

- Capacity, tons max 102

- The volume of silos is total, m³ 68

- The capacity of the first level, tons 60

- First level volume, m³ 40

- Capacity of the second level, tons 42

- Second -level volume, m³ 28

- Weight, kg 8750

Автоматизированные асфальтовые заводы

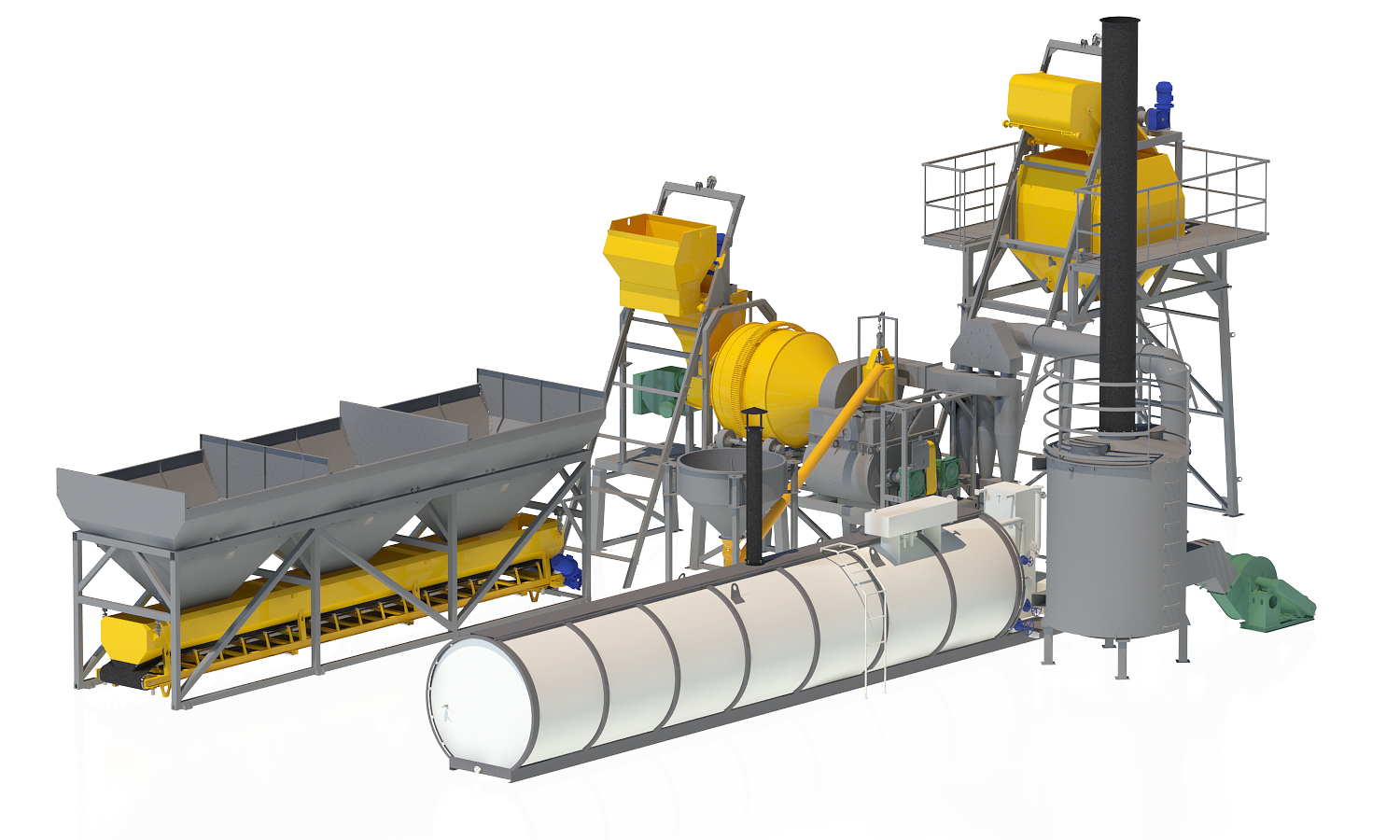

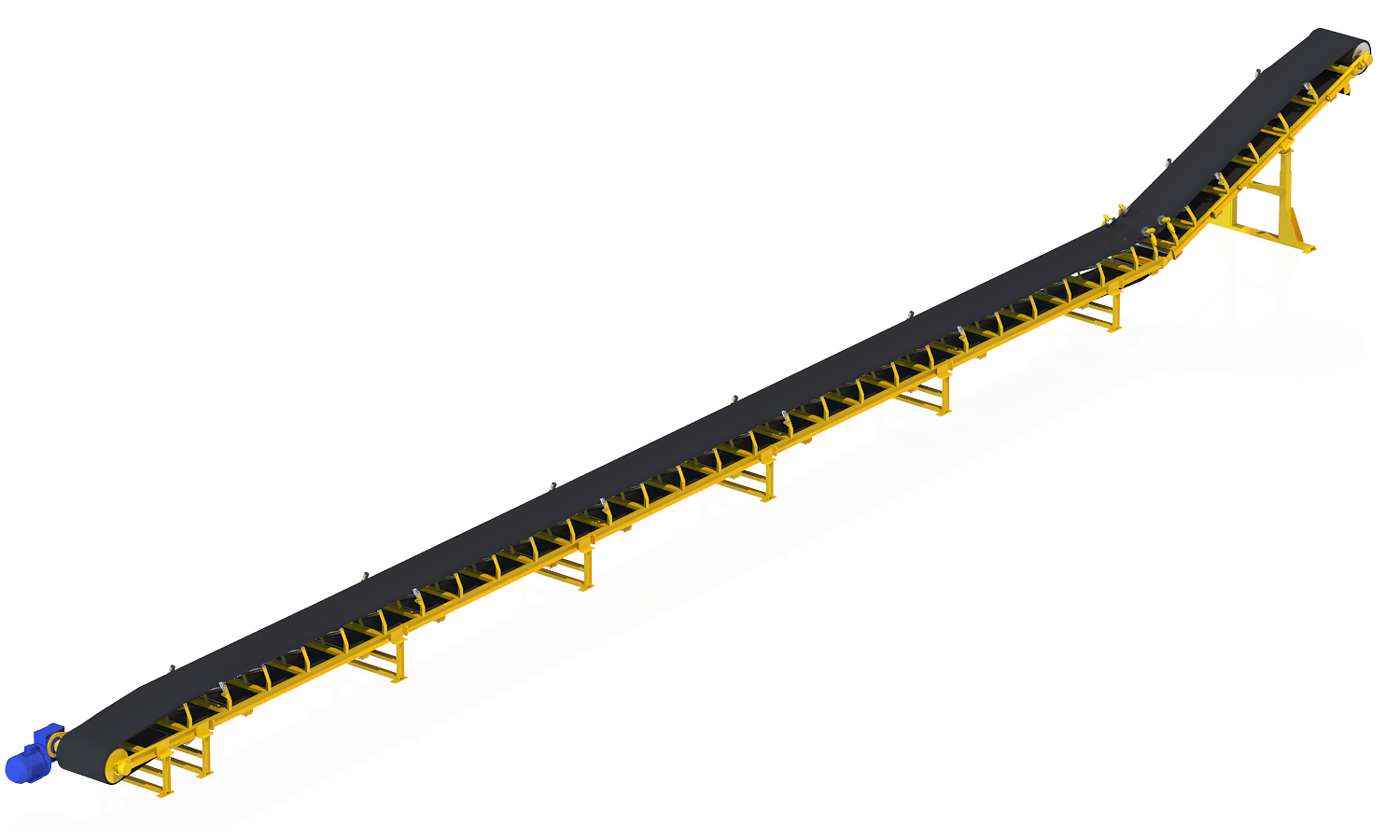

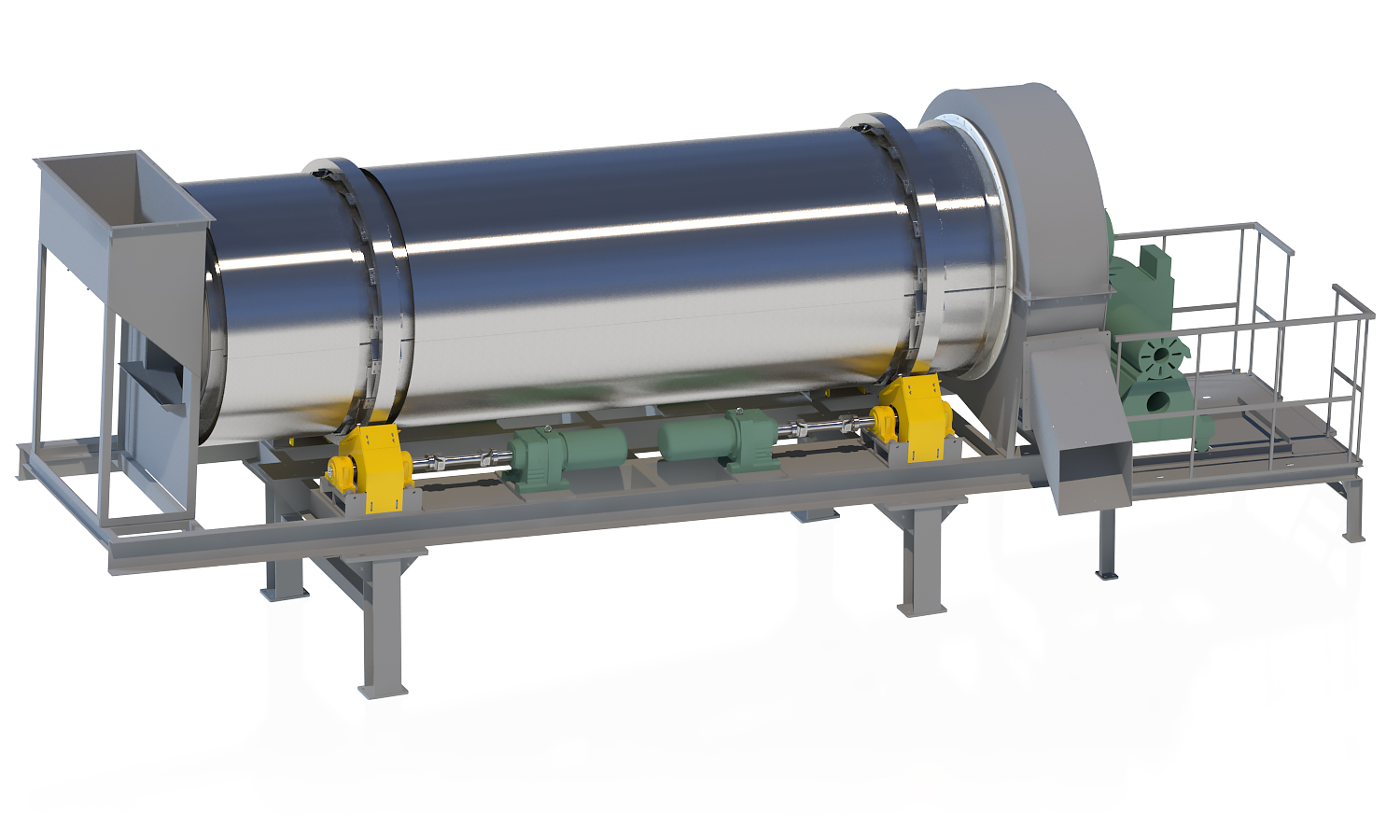

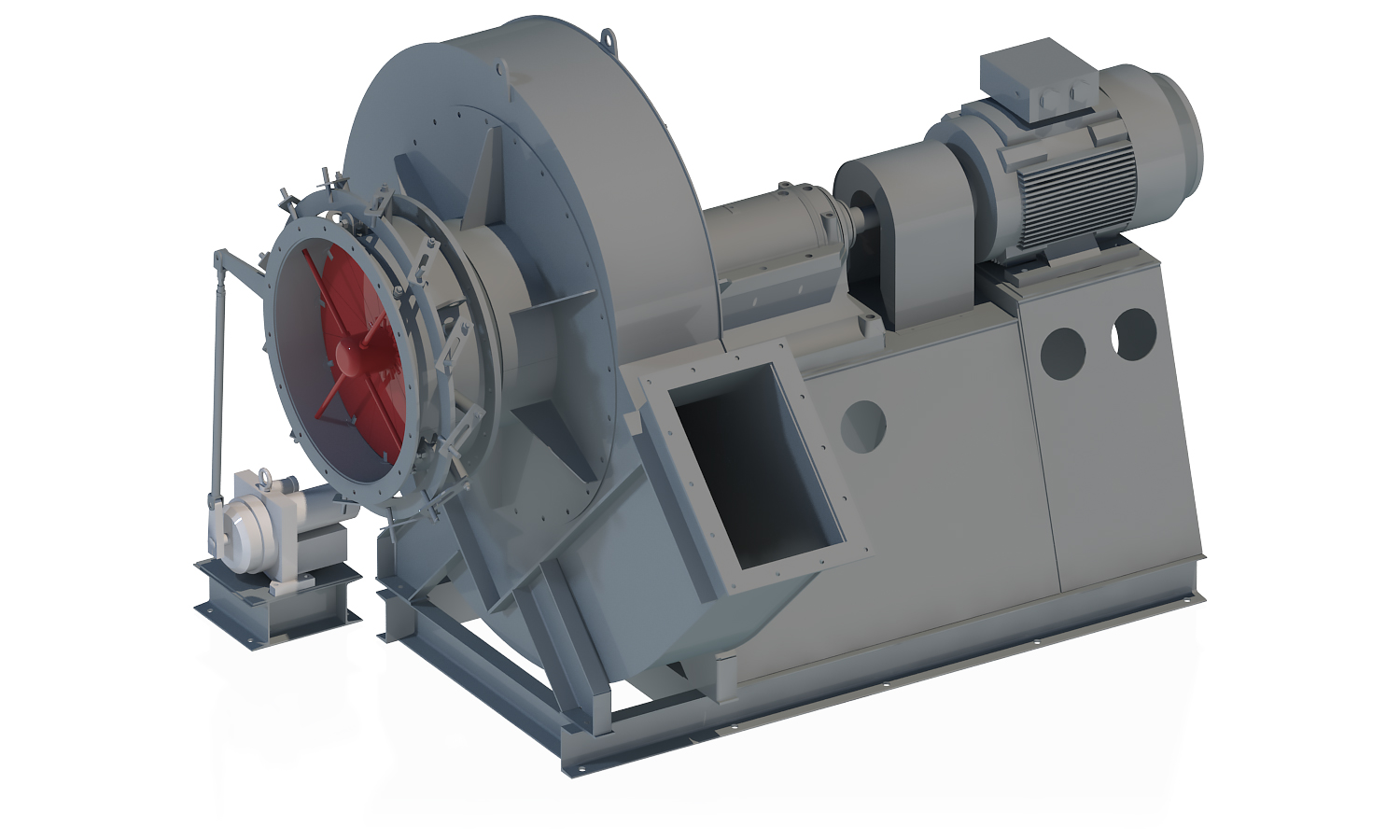

When loading dosing hoppers with inert materials (crushed stone and sand), they enter the drying drum in certain proportions, where they are dried and heated to 160 ° C by means of heating from the burner. The resulting dust and exhaust gases through the air duct system enter the filter unit, where the dust is separated and the exhaust gases are filtered. The separated dust is dosed and used to produce asphalt concrete.

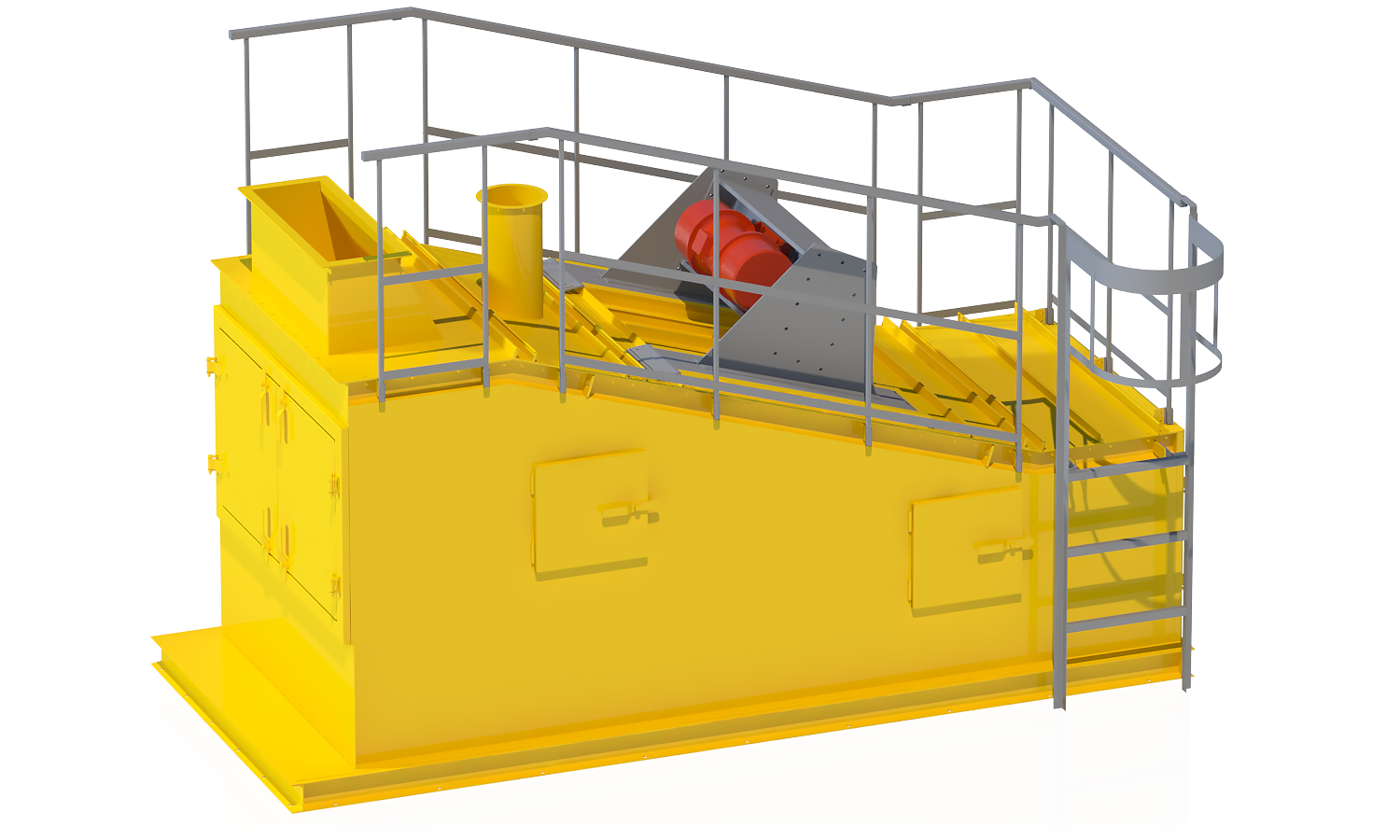

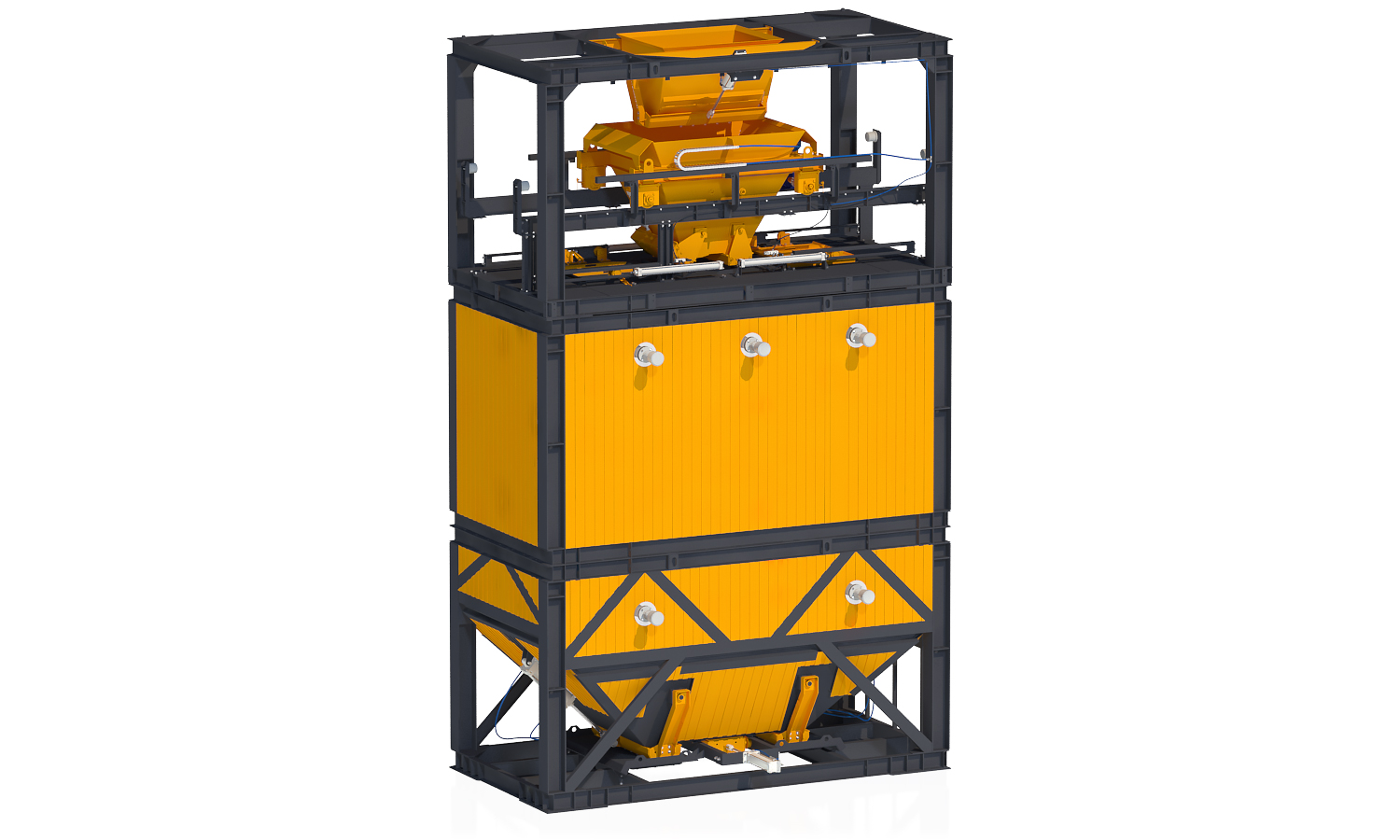

После прогрева инертные материалы по элеватору поступают в грохот. Грохот в свою очередь разделяет материалы по фракциям и отделяет негабаритные инертные, которые в дальнейшем утилизируются. Разделенные по фракциям горячие материалы поступают в накопительные бункера горячих инертных материалов. Каждая их фракций взвешиваются на весовом дозаторе и в определенных пропорциях (заданных исходя из рецептуры асфальтобетона) попадают в смесительный барабан.

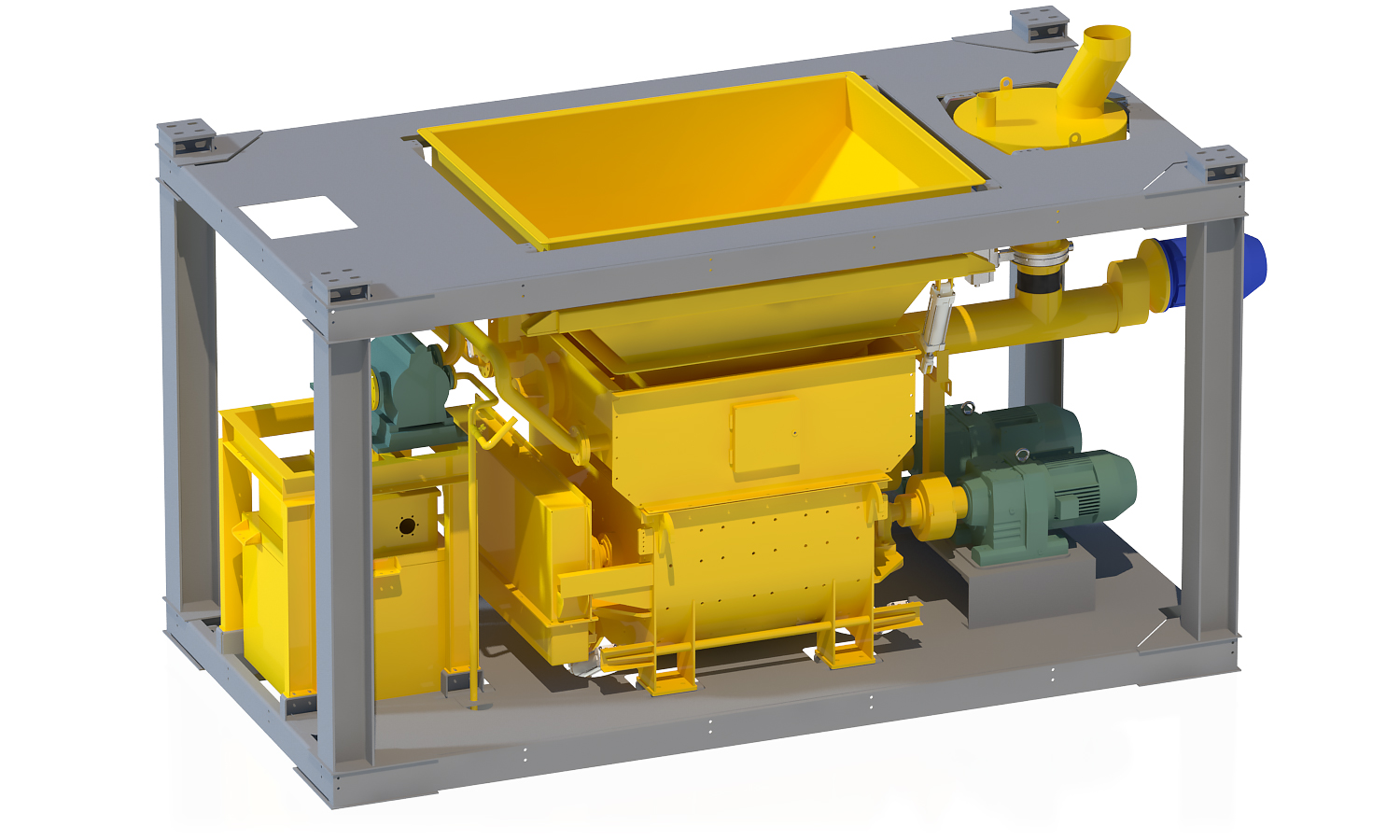

In front of the mixing drum, mineral powder and bitumen dispensers are also installed. Mineral powder from the silo is fed into the batcher, weighed and sent to the dryer drum. In the same weigher, dust is weighed, which is filtered in the filter unit and used as it accumulates in the dust silo.

The bitumen is heated up to 150 °C in the bitumen storage, it enters the dispenser through the heated line, is weighed and pumped into the mixer. Initially, dry materials (crushed stone, sand, mineral powder) are mixed in the mixer, after bitumen is supplied, the final mixing takes place, which lasts no more than 20 seconds.

Ready asphalt comes from the mixing drum directly into the body of the truck.

Comes in different models, the selection of the necessary equipment assists the Sales Manager.