Winter concrete plants

Showing all 8 results

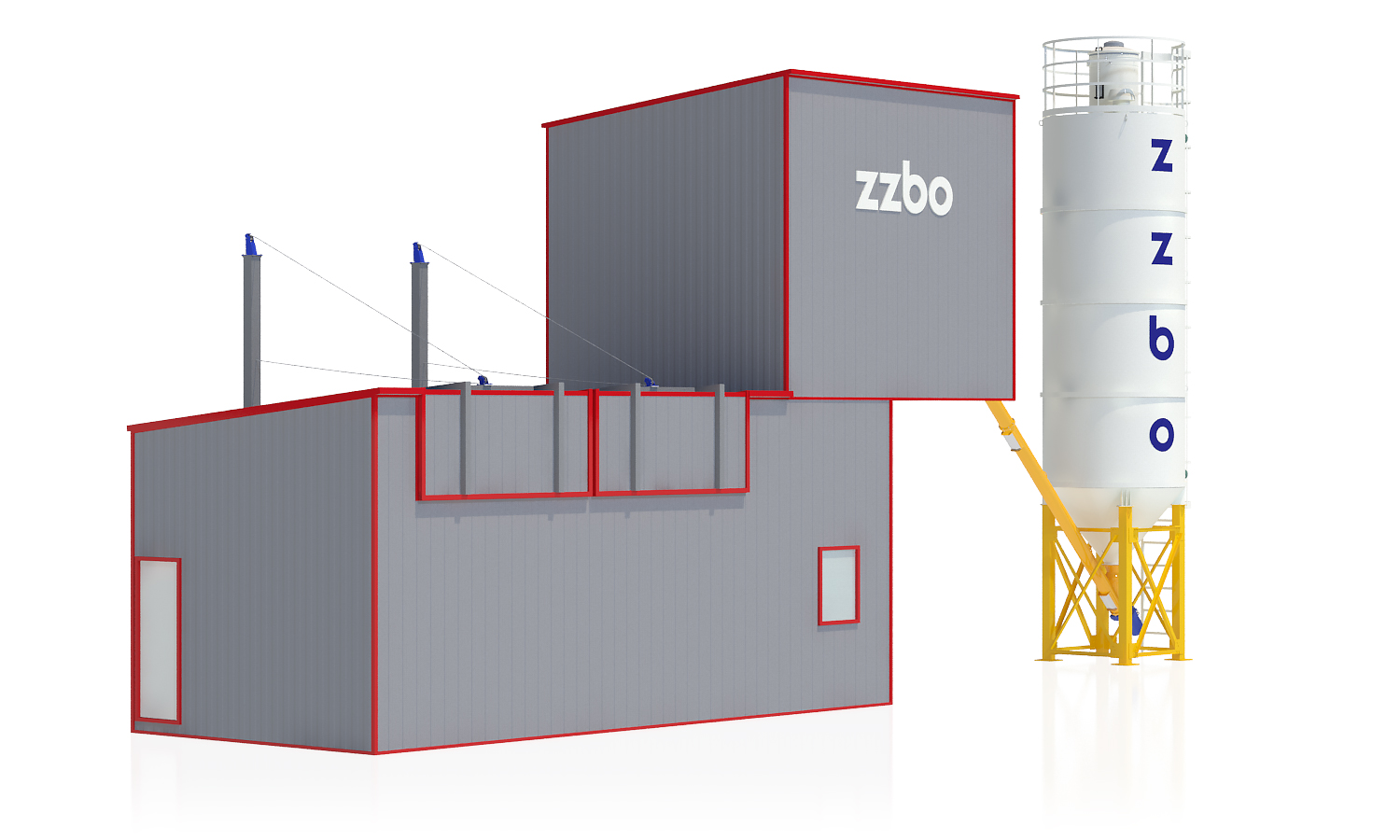

37 025 922 ₸

- Capacity, cu m per hour 10...20

- Режим работы автомат "одна кнопка"

- Concrete mixer BP-1G-500s

- Bunkers (number x volume m3) 2 x 4 = 8

- Silo capacity (optional), tons from 22

- Design all-weather

- Load of inert materials into the concrete mixer skip

37 736 937 ₸

- Capacity, cu m per hour 12...25

- Режим работы автомат "одна кнопка"

- Concrete mixer BP-2G-375s

- Bunkers (number x volume m3) 2 x 4 = 8

- Silo capacity (optional), tons from 22

- Design all-weather

- Load of inert materials into the concrete mixer skip

66 072 600 ₸

- Capacity, cu m per hour 20...30

- Режим работы автомат "одна кнопка"

- Concrete mixer BP-2G-750s

- Bunkers (number x volume m3) 2 x 12 (optional 4 x 6)

- Silo capacity (optional), tons from 22

- Design all-weather

- Load of inert materials into the concrete mixer skip

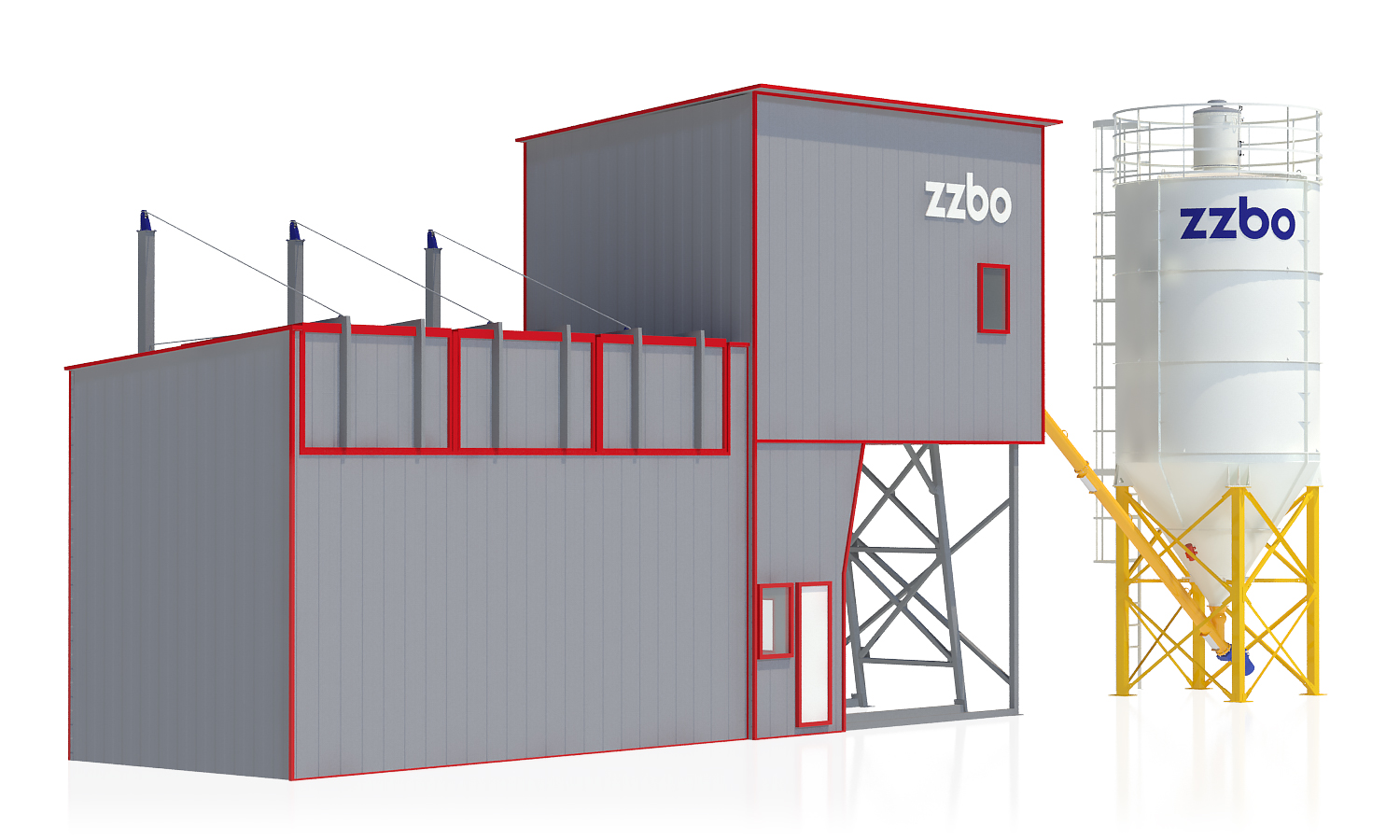

87 482 426 ₸

- Capacity, cu m per hour 35...45

- Режим работы автомат "одна кнопка"

- Twin-shaft concrete mixer BP-2G-1200s

- Bunkers (number x volume m3) 3 x 12

- Silo capacity (optional), tons from 50

- Design all-weather

- Load of inert materials into the concrete mixer skip

101 536 576 ₸

- Capacity, cu m per hour 40...60

- Режим работы – автоматический, "одна кнопка"

- Twin-shaft concrete mixer BP-2G-1500s

- Hoppers (number of x capacity, cu m) 3 x 12

- Silo capacity (optional), tons from 50

- Design all-weather

- Load of inert materials into the concrete mixer skip

114 973 213 ₸

- Capacity, cu m per hour 70...90

- Режим работы автомат "одна кнопка"

- Twin-shaft concrete mixer BP-2G-2250s

- Hoppers (number of x capacity, cu m) 3 x 18

- Silo capacity (optional), tons from 100

- Design all-weather

- Load of inert materials into the concrete mixer skip

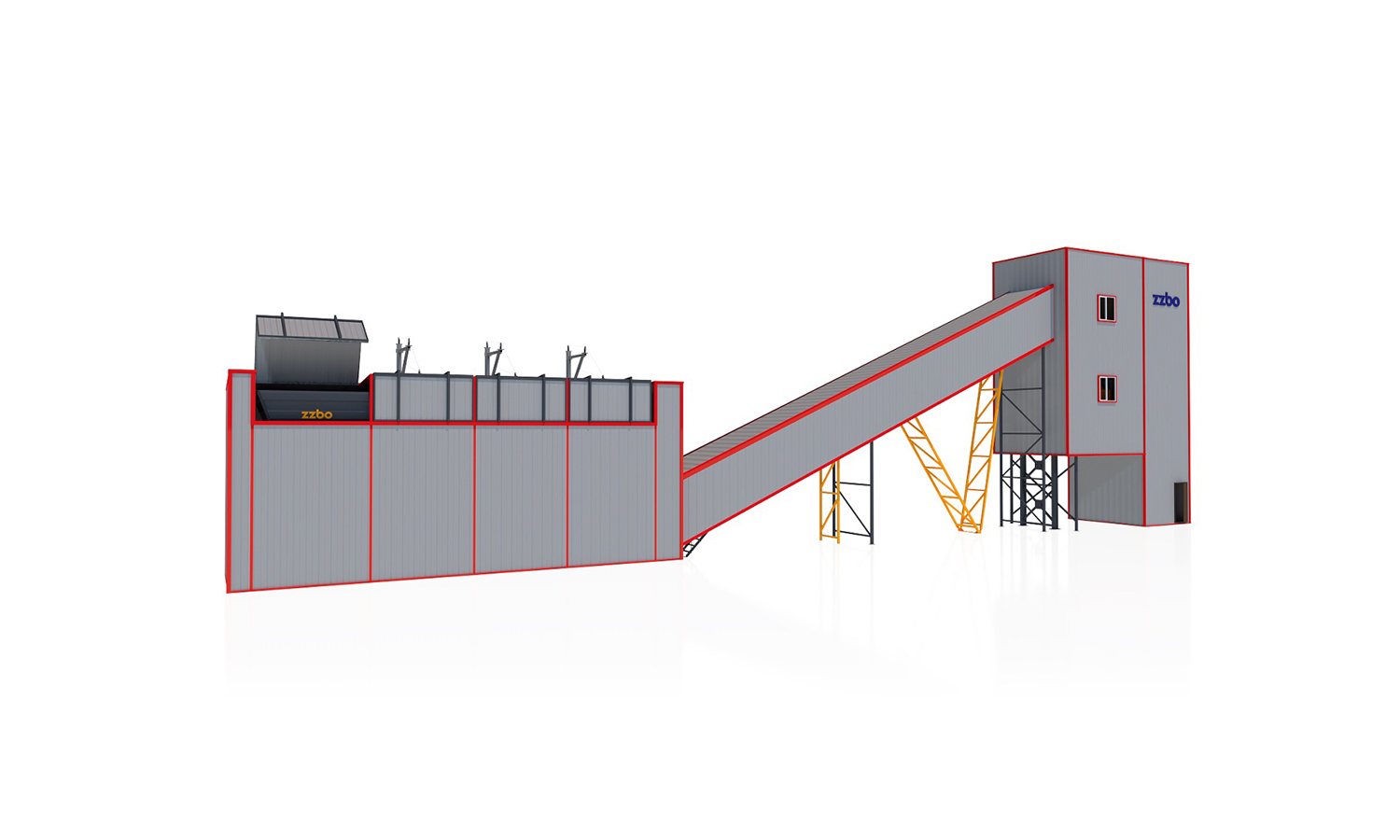

185 366 726 ₸

- Productivity, m³ hour 90...144

- mode auto

- Concrete mixer PD-2G-3000 3000 l loading

- Hoppers (number x volume m³) 4 x 20

- Silo capacity (optional), tons 160...960

- Design winter

- Load of inert materials into the concrete mixer belt conveyor

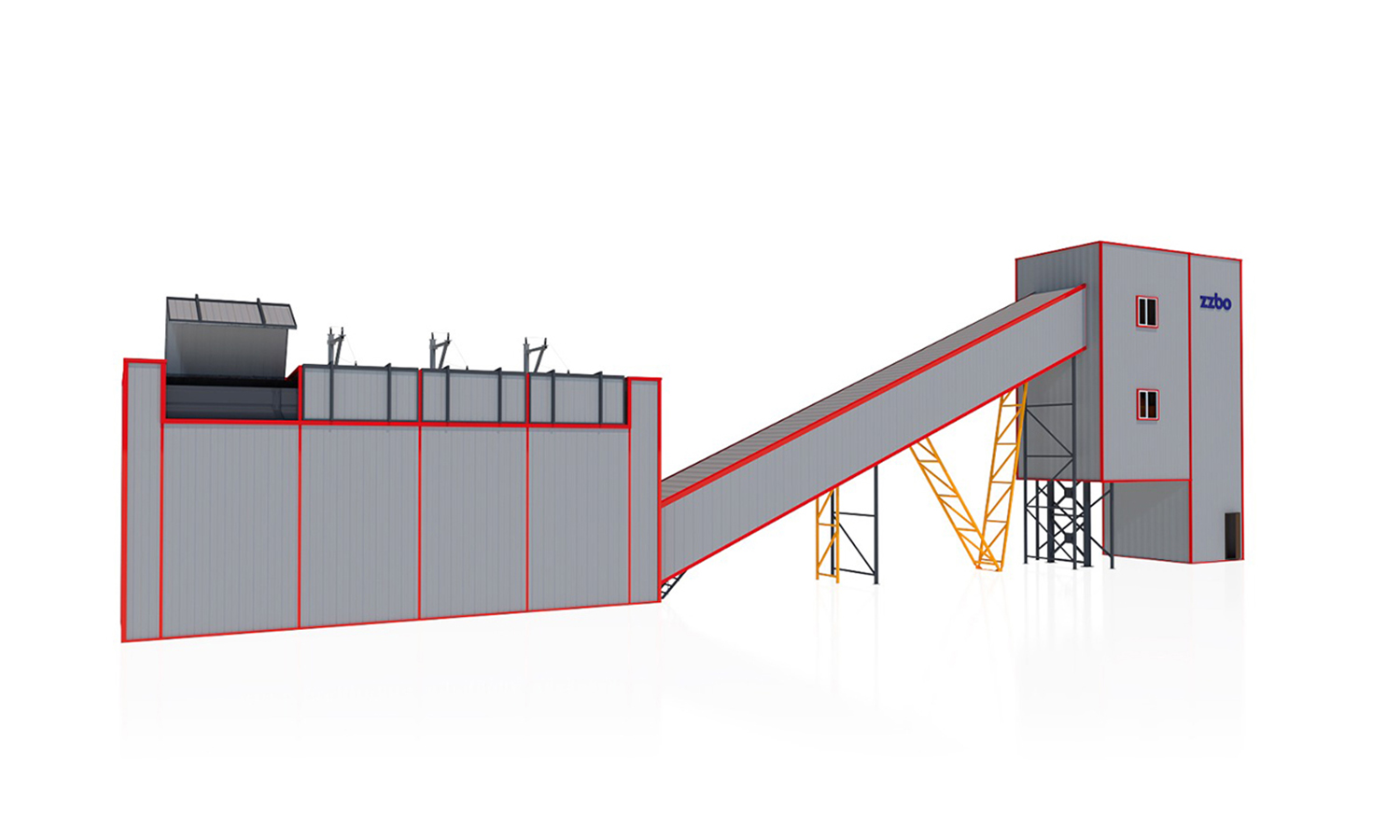

234 279 783 ₸

212 633 176 ₸

- Productivity, m³ hour 110...216

- mode auto

- Two-shaft concrete mixer BP-2G-4500 4500 liters for loading

- Hoppers (number x volume m³) 4 x 30

- Silo capacity (optional), tons 160...2060

- Design winter

- Load of inert materials into the concrete mixer belt conveyor

Winter (all-season) concrete plants of the “FLAGMAN” series

Concrete plants "FLAGMAN" produced by ZZBO have already received well-deserved recognition among developers in Russia and foreign countries. It should be noted that concrete plants of the FLAGMAN series mobile, i.e. if necessary, they can be easily dismantled, transported and installed at another site.

The quality of the concrete mixture and the reliable operation of the mechanisms are not all the advantages of our equipment. Unlike companies in Germany, Turkey and other countries that supply concrete mixing equipment, which produce a winter concrete plant in a special design, for the ZZBO there is no need to divide its equipment into a winter or summer concrete plant. Since the concrete production technology requires ensuring the temperature of the components mixed in the concrete mixer is not lower than +5°C, the customer can be offered, instead of the basic configuration, an adjusted winter configuration of the concrete plant. It includes equipment mass-produced by ZZBO (twin-shaft concrete mixer, trestle for an automixer, dosing complex, etc.), and for winter operation options are added - thermal equipment of a concrete plant: steam generator PG-1000 or heat generator TGV-250 and special registers for heating bunkers of inert materials and production premises.

The main preparation activities all-season concrete plant "FLAGMAN" produced by ZZBO for operation in winter conditions at temperatures down to minus 25 degrees will include the installation of load-bearing metal structures for their subsequent cladding with polycarbonate or sandwich panels and the correct placement of thermal circuits that ensure a positive temperature in the premises of the concrete plant of at least 10-15 degrees Celsius. Due to the fact that the thermal insulation is removable, the customer receives an all-season concrete plant. Together with ZZBO specialists, the customer must determine at what stage of installation of the BSU to carry out preparatory work for the winter period. Commissioning, in accordance with the regulations, is carried out by the ZZBO, and the installation of roof panels and wall panels, windows, the manufacture and installation of insulated metal doors and gates can be carried out by third parties after the concrete plant is put into operation.

Having thus received all-season concrete plant produced by ZZBO, the customer is obliged to comply with some requirements for adjusting summer technical standards for the production of concrete mixtures in winter conditions. Water must be supplied to the concrete mixer heated, the mixing time of the concrete mixture must be increased by one and a half times, quick-hardening cements, etc. are recommended.