QUICK BETON-95 concrete plant

70 173 376 ₸

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

24 011 624 ₸

- BP-2G-2250 Twin-shaft concrete mixer

- Pneumatic valve double

- Connection set for pneumatic equipment

- Броня сменная чешуйчатого типа. Толщина брони 16 мм. Материал: Чугун ЧХ16Н2

- Changeable blades. Material: ЧХ16Н2Т cast iron (chromic high alloy wear-resistant)

- Automatic central lubrication system

- Electricity to connect the remote control

- Maintenance kit (three armor, blade, needle)

- Concrete mixer machinery certificate

29 956 472 ₸

- Установка на раме опорной РО-95Л. Установка без фундамента.

- Inert materials hopper 4 pieces of 10 cubic meters. meters (4 x 10)

- Brush for cleaning the conveyor belt

- Herringbone tape 800 / 24000mm

- Lower spiral roller (to prevent descent of tape)

- Pneumatic distributors - 4 pcs.

- Filter regulator - 1 pc.

- Vibrators MVE 3003 - 8 pcs.

- Vibroplastiny with shock-absorbing cushions

- Conveyor inert materials (0-3800 kg dose).

- Lined drive motor drum 18.5 kW with soft-start system

- Drum tension station

- Load cells 3 tons - 4 pcs.

- CAS connecting box

- Signal amplifier - weight sensor

5 123 664 ₸

- Mounting frame (powder coating). Weight - 200 kg

- Cement dispenser, dosage - 900 kg (powder coating):

- Three inlet pipes for augers (Two are covered with lids)

- Connecting outer sheath with collar clamps

- Overpressure system

- Unloading disc damper ∅200

- Strain gauges - 3 pcs.

- Signal amplifier - weight converter - 3 pcs.

- Pneumatic distributors - 4 pcs.

- Vibrator MVE41 - 1 pc.

- Water dispenser, dosage - 450 liters (powder coating):

- Strain gauges - 3 pcs.

- Unloading disc pneumatic valve ∅80 - 1 pc.

- Water dump pump

- Controlled water and chemical supply system

- Chemical additives dispenser, dosage - 60 liters, made of stainless steel:

- Strain gauges - 2 pcs.

5 901 168 ₸

- Software on your own SCADA system complete with a monoblock: accounting for the consumption of materials and equipment operation, remote access and control over the work in the local network

- Automatic operation by pressing "one" button

- Recipe storage database for concrete production

- Programmable Logic Controller

- Сontrol panel case protection - IP54

- Power cabinet case protection - IP54

- Control, protective and switching equipment "Omron", "Siemens"

- Set of diagrams and instruction manual

286 832 ₸

- The pump Calpeda MXH 202E assembled for chemical supply. additives

- Capacity - 80 liters/min

- Power - 0.33 kW

- Weight - 6.9 kg with packaging

- Machinery certificate

1 172 080 ₸

- operator cabin built (coating: zinc)

- Gangway (coating: zinc)

- Sound insulation, protection against rain

- Three viewing windows (PVC, double glazed windows), insulated door with lock

- Lighting

2 475 200 ₸

- Hardware for assembly RBU: metering complex overpass screw silage

- Hardware, accessories

- Wire for screw fixing

- Kit for connecting the database (pnevmotruba, sleeves, bends, RVC 51-70 clamps, duct PVC-5-C-60)

- Limit switch for the database

- Kit vodopodvedeniya (pipe bends, sleeves, T-joints, anchor bolts, brackets)

- Kit RBU pneumatic (air tubing, pnevmotruba, fittings, hardware)

- Set of cables

- Couplings (5 titles)

- compactor

- Acid sealant TempPlus

- Power and control cables, protected by metal hose (in mobile plants they are laid in frame)

- Set of locking sensors and executing mechanisms position sensors (skip, mixer's gate, etc.)

23 922 808 ₸

- Twin-shaft concrete mixer MAO 2250

- Multi-channel uniform water spray system

- Replaceable wear-resistant Ni-Hard cast iron armor, strength 500 HB

- The hydraulic shutter drive system

- Connection set for pneumatic equipment

30 606 576 ₸

- Planetary concrete mixer MPC 2250

- Mixer drive - 74 kW

- Replaceable wear-resistant armor made of cast iron with a strength of 500HB

- The sector valve with rubber seal is equipped with a hydraulic drive with the possibility of manual opening

- Inspection hatches are equipped with an access security system

605 453 ₸

- Lattice with section 100x100 (70x70). Cell height 70 mm. Weight 575 kg

- Cement filter AIRFILL25 assembly (Turkey) in a rigid package

- Cartridges pneumatic cleaning system

- Adjusting ring

- Operational documentation

- Airfill v25 cement filter with a vibration cleaning (Türkiye)

- Adjusting ring

- Operational documentation

3 471 104 ₸

- Auger assembly

- Pipe Diameter 273 mm, tube length of 12 000 mm

- Drive: gear motor. Power 15 kW

- Inspection window for cleaning and maintenance

- Operational documentation

7 536 984 ₸

- Silo bank (V=63m³)

- Mounting frame

- Stairs

- Cover protection enclosure

- Loading pipe d 102 with connection lock

- Connecting flanges for installation cement filter emergency valve, level sensors, aeration and vibrator

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection is made with a two-component primer-enamel PentriProtect PUR 700 based on polyurethane-acrylic resin in the ATIS spray booth

- Machinery certificate

- Cement filter with vibration cleaning FCS-24 NEON assembled

- Filter elements - 14 pieces

- Stainless alloy steel body

- Vibrator - cartridge vibration cleaning system

- Silage setting ring

- Lid

- Machinery certificate

146 328 ₸

- Emergency pressure relief valve PV273 assy

- Adjusting ring

- Operational documentation

77 168 ₸

- Cement level sensor G2 1/2 220V assy in a package

- Adjusting ring

- Operational documentation

128 128 ₸

- Butterfly valve DN300

- Handle for gate control

- Operational documentation

7 534 800 ₸

- Silo Tank (V = 68 m3): cover - 4 sectors, cylindrical sections - 16 pcs, large cone - 4 sectors, small cone

- Mounting frame

- Stairs

- Cover protection enclosure - 11 sectors

- Loading pipe d 102 with connection lock

- Inspection hatch (Viewing window for inspection and cleaning of the cone)

- Connecting flanges for installation cement filter emergency valve, level sensors, aeration and vibrator

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection is made with a two-component primer-enamel PentriProtect PUR 700 based on polyurethane-acrylic resin in the ATIS spray booth

- Frame for transportation

- Hardware for the assembly of a silo

- Polyurethane sealant Soudaflex FC 40 gray 600 ml - 10 tubes

- Machinery certificate

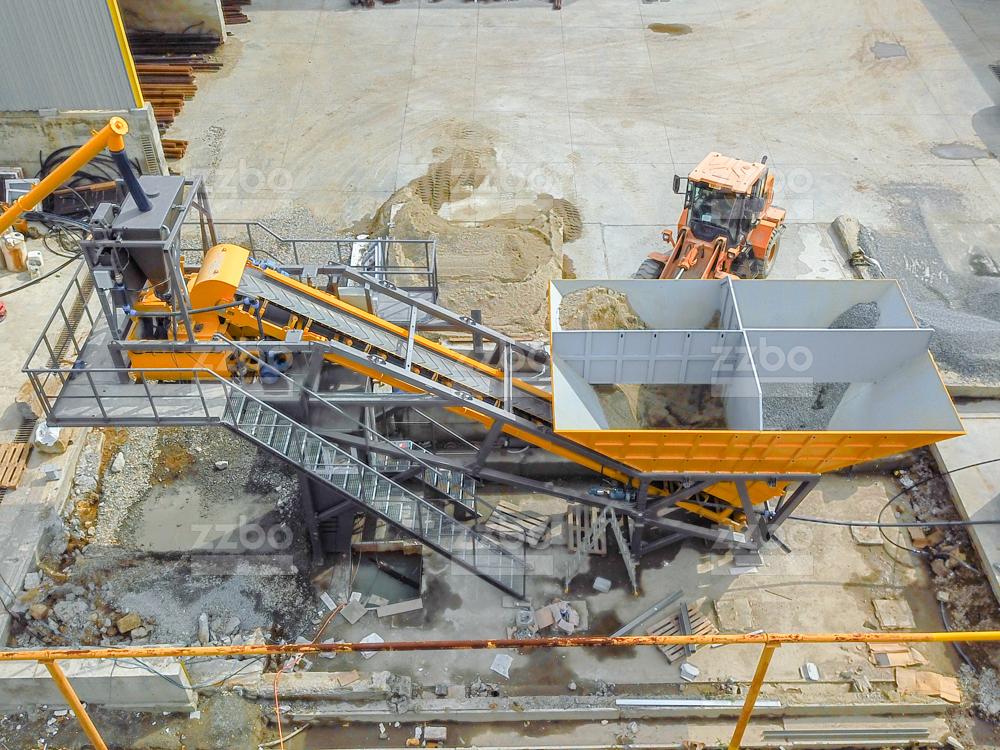

The QUICK BETON-95 concrete batching plant is a compact belt batching plant manufactured by ZZBO.

QB-95 completes the line of concrete plants with a capacity of 35 m³ concrete/hour, 55 m³ concrete/hour, 75 m³ concrete/hour, 95 m³ concrete/hour. These are quick-mounted RBUs that do not require the preparation of a high-strength surface for its installation, as well as the ability to install a frame chassis for more mobile operation.

On-site mobile concrete plant QUICK BETON-95, with a capacity of up to 95 m³ of concrete per hour of operation.

Transportation in one 40 ton container or euro truck. The boards of the dosing complex are folded and transported in a separate transport bed.

The plant is supplied already fully prepared for the work, does not require a long setup and preparation of the foundation.

It is set in the open air, any dense surface without preparation or any room with a ceiling height of not less than 9.5 meters.

Commissioning means connecting the 380 volt voltage and supplying the water supply. Takes no more than two hours!

The principle of automatic operation:

- Inert materials (sand, screenings, crushed stone, etc.) that will be used in the production of concrete mortar are distributed among the inert bin compartments by name. The number of bins is 4 pcs. In the same way, cement in the silo, water and additives are distributed according to the class in the supply tanks.

- After selecting a specific concrete recipe, the required volume (m³) is entered. After that, the plant starts production.

- Inert materials are batched separately according to set weight. The batching is performed on the belt conveyor on which they are fed by opening of the hopper's gate.

- Batched inert materials are loaded into the mixer on this weigh belt conveyor.

- Cement, water and various chemical additives are fed to the corresponding dispensers where they are weighted according to the formula specified in the automation system.

- After dosing, all components of the concrete mortar are fed one by one through the dispenser valves into the concrete mixer.

- The mixture of all components is mixed in a twin-shaft concrete mixer for a certain time and is fed in the form of a concrete solution through the mixer drain valve.

Twin-shaft mixer PD-2G-2250

Twin-shaft concrete mixer consists of a stationary welded body with two horizontal shafts с закреплёнными на них лопатками и скребковыми лопастями. Валы соединены между собой валом-синхронизатором для защиты привода. Загрузка компонентов бетонной смеси осуществляется непосредственно в корпус бетоносмесителя, для защиты от попадания посторонних предметов предусмотрена защитная решетка.

Is driven by Two electric motors 30 kW each (total capacity of 60 kW) across remennuyu peredachuEquipped with a jacket and two reinforced planetary gear unit "Just Drive ". mixing shaft rotation speed 32 revolutions per minuteMixer box is coated from the inside by wear-resistant armor, flake type. . The armour is changeable and fastened on screws. The armour consist of separate elements thus allows to change only worn out parts, it makes maintenance and repair works easier. The ready-to-use mix is discharged through a window in the bottom of the body closed by with double pneumatic lock.

Concrete mixer is equipped with a automatic central lubrication system bearing units and spray water system.

CAMOZZI pneumatic gate - two-side

In one cycle, 1.5 m³ of concrete is produced. The cycle lasts about 40 seconds. Thus, 3 m³ of concrete is produced in one and a half minutes of operation of the QUICK BETON-95 installation

DK-40 metering hopper

Has a large capacity of 40 m³ of inert materials. These are four bunkers with a volume of 10 m³.

The large loading width of the bunkers is 3.5 meters. The conveyor is equipped with a chevron belt and a lined drum, an anti-slip and self-cleaning system. Weighing conveyor, on suspended strain gauges. Dosage error 1%.

Power conveyor drive 18.5 kW.

The bunkers are equipped with four pneumatic valves. Eight vibration motors are installed on the cone of the bunkers, mounted on a special platform, fixed through four vibration pads of the wall of the bunker cone; the effect of vibration on the inert material occurs with the help of a vibrating plate not in contact with the wall of the bunker. The impact of mechanical destructive force on welded joints of adjacent structures is reduced.

BD-90 block of dispensers

Блок дозаторов показан на рисунке 1, он состоит из рамы, бункера (дозатора) цемента, дозирующего бака воды с насосом, дозирующего бака жидкостных хим. добавок.

Рама сборно-сварная из стали. Дозирующий бак снизу восьмиугольной, сверху четырех угольной формы, образованный пирамидой и ее сечением, сварен из листовой стали. Бункер цемента подвешивается на трех тензодатчиках BSA-500L, также являющимися измерителями массы продукта в бункере. Опора имеет 2 отверстия для крепления тензодатчиков. Бак воды с насосом и бак хим. добавок выполнены в форме прямоугольных призм. Бак воды сварной из листовой стали, бак хим. добавок сварной из нержавеющей стали.

Бак воды подвешивается по такому же принципу, как и бункер цемента. Бак хим. добавок подвешивается на одном тензодатчике BСА-100L, являющимся измерителем массы жидкостной хим. добавки.

Данные с тензодатчиков обрабатываются сумматором, расположенном в распределительном шкафу. После совершения операции дозирования (наполнении баков необходимой для замеса массой цемента, воды и хим. добавки) автоматически отключается подача в баки и открываются заслонки сброса в смеситель.

Next there is complete devastation tanks.

Cement silos, silo piping and augers are always in stock in Zlatoust!

Compressed air system Compressor SB4/F-270.LB50-5.5

Consists of an Italian piston compressor SB4/F-270.LB50-5.5 and a pneumatic system. Capacity 880 liters per minute, power 5.5 kW. Pressure 10 atm. Receiver 270 liters. The compressor is already built into the frame and is protected from the external environment and dust.

Control panel PA-3.0 SCADA-5.0 with monoblock

С помощью системы автоматизации «ПА 3.0» можно управлять бетонным заводом, в ручном и полуавтоматическом режиме работы, используемых для отладки оборудования и отработки рецептов выпускаемой продукции. А также в автоматическом режиме по принципу «одна кнопка», позволяющем получить заданное количество бетона, по выбранному из памяти рецепту и предустановленным параметрам работы оборудования. Расширенные настройки каждого отдельного узла, помогают подстроить работу завода под необходимый технологический процесс производства и добиться максимальной производительности в конкретных условиях производства и перестроить цикл за пару минут. Парольная защита разных уровней доступа и функция создания ежедневного отчета на USB накопитель в базовой комплектации.

- Productivity up to 95 m³ per hour of operation

- Twin-shaft mixer, cement savings up to 15% and a high quality mixture of

- Transportation in the first 40 feet container or eurowaggon

- Installed directly on site where the concrete is needed

- It does not require the preparation of the foundation, the launch of the new site in 1 hour

- Software on our own SCADA system complete with a monoblock: accounting of material consumption and equipment operation, remote access and control over the work

- 2 year full warranty

Technical Features

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

г. Astana, prospekt Akžol, Zdanie 44, of. 32

e-mail: sales@zzbo.ru

Artem Kononovich

Director of the branch in Kazakhstan

Phone: +7 (7172) 760-141

e-mail: sales@zzbo.kz

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions