The metering range of the DC-54 (mobile)

24 166 016 ₸

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| Mounting frame. Installation without foundation |

| Bunkers of inert materials 3 pieces of 18 m³ (3 x 18) |

| Preparation under registers installation for heating inert materials |

| Pneumatic valves - 6 pieces |

| Pneumatic dampers - 6 pieces |

| Filter regulator - 1 piece |

| Vibrators MVE 3003 - 6 pieces |

| Inert materials belt conveyor (dosage - 0-3000 kg). Belt speed - 1.6 m/sec |

| Lined drive drum motor 18.5 kW with soft start system (when ordered with remote control) |

| Drum tension station |

| Load cells SBA-3000 - 4 pieces |

| CAS connecting box |

| Signal amplifier - weight sensor |

| Heating registers with flanges - 3 pieces |

| Remote Control Manual |

| Automatic control panel |

| The soft starter, frequency converter |

| Grating on the hopper |

| Compressor ABAC 6000 |

Mobile metering range DC-54 (mobile) is installed on a hard, flat ground, making the foundation and skip pit is required.

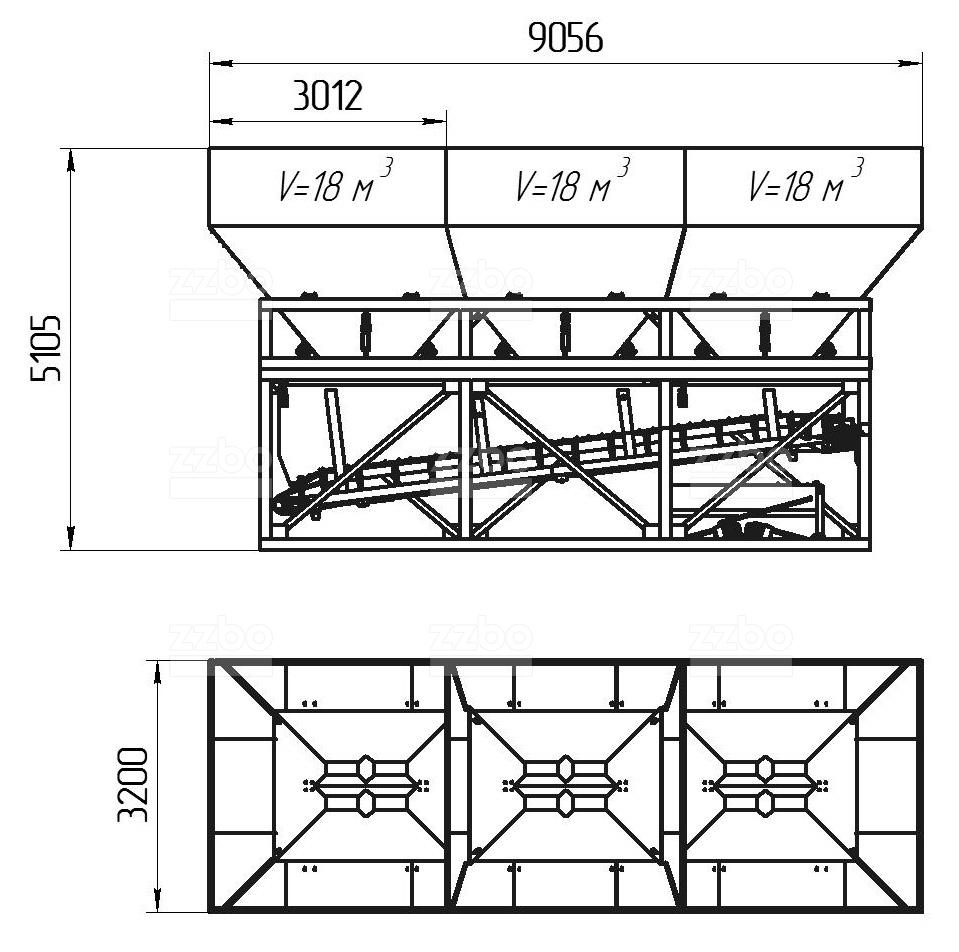

The loading height of the bins of 5.1 meters, width of load over 3 meters.

Three bunkers are installed on a special frame, the volume of each bunker is 18 m³. Each bunker is equipped with two sector gates and vibrators-shaker MVE 300/3 - 6 pieces.

To ensure the performance of the metering complex it must be connected to the compressed air with working pressure of 0.6 ... 0.8 MPa.

Conveyor of inert under the bunkers on 4 load cells with a total weighing weight of 8 tons.

Пульт управления дозирующим комплексом устанавливается в удобном для работы оператора месте. (заказывается дополнительно) Инертные (песок, отсев, щебень и прочее) подаются в бункера с помощью грузоподъемных механизмов, например фронтальный погрузчик.

To protect against falling into the bunker on bunker large fraction optional can be fitted with a lattice cell of any size.

Далее вся работа осуществляется с помощью пульта оператором дозирующим комплексом (возможна поставка дозирующего комплекса с автоматическим пультом управления ПА, для управления дозирующим комплексом в автоматическом режиме). С помощью переключателей открывается затвор первого бункера и подается основная доза первого компонента. Точная дотация осуществляется нажатием кнопки и импульсным открытием заслонки. За набором необходимой дозы оператор следит на цифровом индикаторе табло, которое находится на пульте управления.

In case of difficulty in supplying inert from the bunkers, the operator, by briefly pressing the button, activates the vibrators-shakers MVE 300/3 on the required bunker. As the dose is collected and weighed, the operator turns on the conveyor drive and the weighed dose of inert enters the receiving hopper.

Далее в такой же последовательности осуществляется подача и взвешивание следующего компонента из второго бункера. После разгрузки конвейера дозатора-инертных, цикл дозации повторяется.

Cycle dozacii no more than 12 ... 20 seconds.

Can be supplied in a protective coating of zinc. The coating is applied by cold galvanizing.

- It does not require the production of foundation and skip pit

- Three hoppers of 18 m³ each (total volume 54 m³)

- loading width of over 3 meters, loading height 5.1 meters

- Accurate dosing - accuracy better than ± 1%

- Lined the drive drum, galvanized rollers

Technical Features

- Total maximum volume of bunkers, m³ 54

- Volume of one bunker, m³ 18

- The number of bins, pieces. 3

- The maximum dose weighing kg 3,000

- Batching error,% 1

- Belt speed, m c 1,6

- The pressure in the pneumatic system, MPa 0,6...0,8

- Aggregate size, mm max 70

- Supply voltage, V/Hz 380/50

- Power installed, kW 16,8

- Shutter sector, pneumatic cylinders control, pcs. 6

- Weight, kg 7,500

- Height, mm 5105

- Width, mm 3,200

- Length, mm 9056

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

г. Astana, prospekt Akžol, Zdanie 44, of. 32

e-mail: sales@zzbo.ru

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions