Dosing complex DCM-80

29 261 232 ₸

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| Bunkers of inert BI-80 (4 x 20) - 8 sections. The total volume is 80 cubic meters. meters |

| Preparation under registers installation for heating inert materials |

| Pneumatic equipment - 8 electric pneumatic distributors, a set of fittings and tubes, 8 quick exhaust valves, 1 pneumatic regulator, a filter with a pressure gauge |

| Vibrator MVE 300/3 - 8 pcs. |

| Dispenser inert CI-12 (conveyor) with the lined drive drum. Drive power 18,5 kW |

| Rollers with anti-corrosion coating |

| Strain gauges - 6 pcs. |

| CAS connecting box |

| Signal amplifier - weight sensor |

| Passport to complex metering and purchased products |

| Compressor SB4/F-270.LB50-5.5 |

| Automatic control panel |

| Lattices on bunkers |

| Registers for heating |

| Covers for bunkers |

The total volume of bunkers is 80 m³Four bunkers are installed on a special frame. Each bunker with a volume of 20 m³. Each bunker has two sector shutterings, which is controlled by the pneumatic cylinder installed on it. Due to the use of two shutters: the main and additional, it is possible to achieve high accuracy. On each section, the MVE 300/3 vibrator is installed-only 8 pieces.

To install the DCM-80 complex dosing It does not require the production of special foundation, The complex is set on a flat, dense area.

To ensure the performance of the dosing complex, it must be connected to the compressed air line with a working pressure of at least 0.6 ... 0.8 MPa. To install the compressor, a platform for its placement is already provided in the frame of the metering complex. This allows Close the compressor from the influence of dust from the plant and atmospheric precipitation.

The inert dispenser (conveyor) DI-12 is installed under bunkers on six high-precision tensodists with a total carrying capacity of 12 tons.

Инертные (песок, отсев, щебень и прочее) подаются в бункера с помощью грузоподъемных механизмов. Для защиты от попадания в бункера крупных фракции на бункера могут быть установлены решетки с ячейкой 100 мм х 100 мм или других размеров (опция).

Further, all work is carried out using the control panel (depending on the selected configuration, delivery with an automatic control panel is possible). The gates of the two sections of the first bunker are opened and the main dose of the first component is supplied. Accurate dosing is carried out by automatic and pulsed opening of the bunker gates.

The operator monitors the set of the required dose automatically. In case of difficulty in supplying inert from the bunkers, vibrators-shakers MVE 300/3 are briefly activated on the required section of the bunker. In process of collection and weighing, the automation turns on the drive of the conveyor-dosing device DI-12 and the weighed dose of inert enters the receiving hopper. Then, in the same sequence, the next component is fed and weighed from the second hopper.

After unloading conveyor-dispenser inert CI-12 dosing cycle repeats.

Can be supplied in a protective coating of zinc. The coating is applied by cold galvanizing.

- Does not require foundation

- Perevozitsya in 1 evrofure

- 4 the hopper 20 cubes each (total 80 cu. Meters)

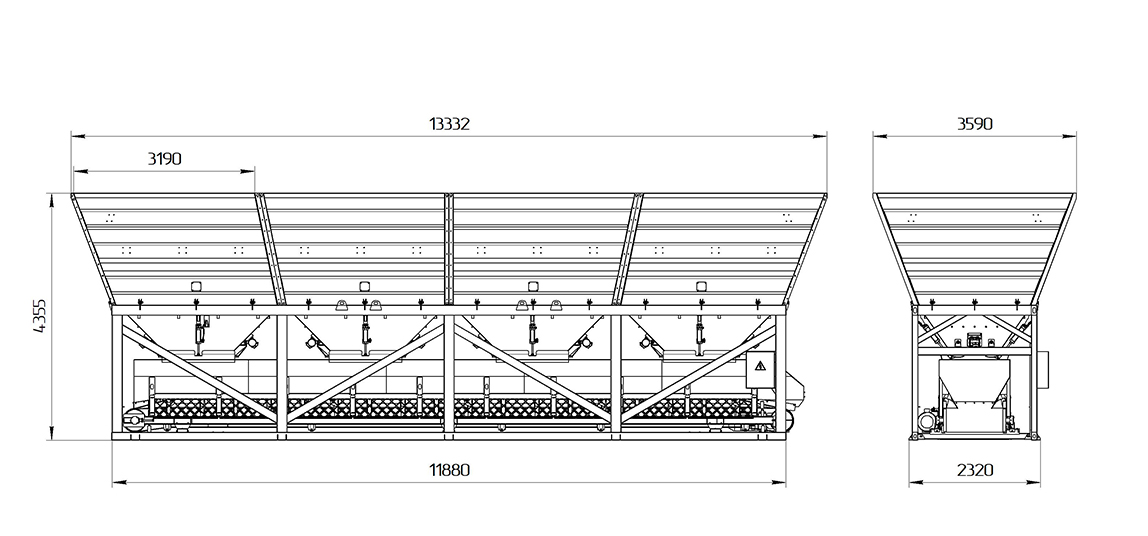

- Loading width 3.2 meters, loading height 4.3 meters

- Accurate dosing - accuracy better than ± 1%

- Lined the drive drum, galvanized rollers

Technical Features

- Total volume of bunkers, m³ 80

- Volume of one bunker, m³ 20

- Vibrator power, kW 4

- The maximum dose weighing kg 6000

- Batching error,% ±1

- Belt speed, m c 1,9

- The pressure in the pneumatic system, MPa 0,6...0,8

- Aggregate size, mm max 100

- Number voltage, V/Hz Reject hopper capacity (at a density of 1.8 t/m³), m³ (t)

- Total installed power, kW 20,9

- Weight, kg 11600

- Height, mm - only 4 pieces.

- Width, mm 3590

- Length, mm 13332

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

г. Astana, prospekt Akžol, Zdanie 44, of. 32

e-mail: sales@zzbo.ru

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions