Dosing complex DKP-10

7 081 088 ₸

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| Bunker-inert (2 x 5) - 2 sections. The total volume is 10 cubic meters. meters |

| Sector valves, with control of pneumatic cylinders - 2 pcs. |

| Pneumatic equipment - 2 electric pneumatic distributors, a set of fittings and tubes, 2 quick exhaust valves, 1 pneumatic regulator, a filter with a pressure gauge |

| Вибратор MVE 300/3 - 2 шт. |

| The support frame, installation without foundation |

| Дозатор инертных (весовой конвейер) с футерованным приводным барабаном. Мощность привода 4кВт |

| Rollers with anti-corrosion coating |

| Load cells 2 tons - 4 pcs. |

| CAS connecting box |

| Signal amplifier - weight sensor |

| Passport to complex metering and purchased products |

| Compressor SB4/C-200.LB30-3.0 |

| Пульт управления дозирующим комплексом для ДКП |

| The soft starter, frequency converter |

| Grating on the hopper |

For installation of dosing complex DKP-10 It does not require the production of special foundation, The complex is set on a flat, dense area.

Two bunkers are installed on a special frame. Each bunker with a volume of 5 cubic meters. meters has one sector shutter, which is controlled by a pneumatic cylinder installed on it. A vibrator-shaker is installed on one bunker (under the sand).

To ensure the operation of the dosing complex, it must be connected to a compressed air line with a working pressure of at least 0.6 MPa. We recommend using compressors.

The inert batcher (weight conveyor) is suspended under the hoppers on four high-precision load cells a total capacity of 8 tons.

Inert materials (sand, screenings, crushed stone, etc.) are fed into the bunkers with the help of hoisting mechanisms. Loading height minimum 2.5 meters, suitable fit.

Далее вся работа осуществляется с помощью пульта управления (зависит от выбранной комплектации, возможна поставка с автоматическим пультом управления). Открывается затвор первого бункера и подается основная доза первого компонента. Точная дозация осуществляется автоматикой и импульсным открытием затвора.

Automatically monitors the set of the required dose. If it is difficult to supply inert from the bunkers, the vibrator-shaker is briefly activated on the required bunker. As the set and weighing, the automation turns on the drive of the inert batcher (weight conveyor) and the weighed dose of inert enters the receiving hopper. Then, in the same sequence, the next component is fed and weighed from the second hopper.

The maximum dose of a single dosing on the weight conveyor - 1200 kg.

After unloading the weight conveyor, the dosing cycle is repeated.

- It does not require the production of foundation

- Transported in 6 meter truck

- 2 bunkers of 5 cubic meters each (total volume 10 cubic meters)

- Loading width 2.6 meters, loading height 2.5 meters

- Accurate dosing - accuracy better than ± 1%

- 2-year warranty

Technical Features

- The total volume of bunkers, the cube. m. 10

- The volume of the hopper, the cube. m. 5

- The number of bins, pieces. 2

- The maximum dose weighing kg to 1200

- Batching error,% ±1

- Belt speed, m c 1,3

- The pressure in the pneumatic system, MPa 0,6

- Aggregate size, mm max 100

- Supply voltage, V/Hz 380/50

- Power installed, kW 4,6

- Shutter sector, pneumatic cylinders control, pcs. 2

- Weight, kg 2,250

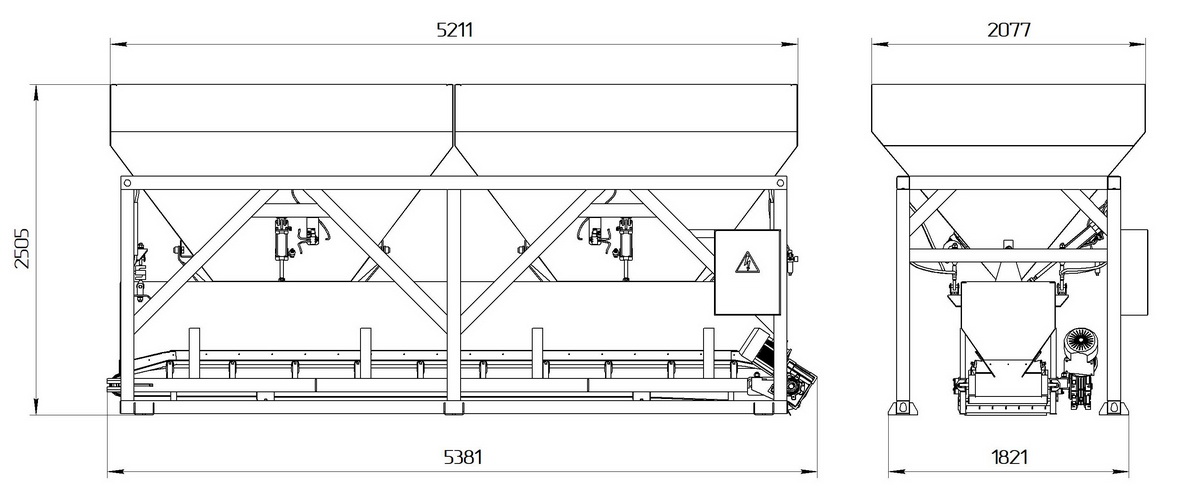

- Height, mm 2505

- Width, mm 2077

- Length, mm 5211

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

г. Astana, prospekt Akžol, Zdanie 44, of. 32

e-mail: sales@zzbo.ru

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions