BP-2G-750 Twin-shaft concrete mixer

11 394 795 ₸

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| BP-2G-750 Twin-shaft concrete mixer |

| Pneumatic gate - two-side |

| Connection set for pneumatic equipment |

| Changeable armour, flake type. Material – wear-resistant cast iron 12 mm thick |

| Спицы усиленные (стальное литье) крепление типа "кулак" |

| Changeable blades. Material: ЧХ16Н2Т cast iron (chromic high alloy wear-resistant) |

| Устройство равномерного распределения воды с присоединительным диаметром 2" |

| Electricity to connect the remote control |

| Maintenance kit (three armor, blade, needle) |

| Purchased parts machinery certificates |

| Concrete mixer machinery certificate |

| Concrete mixer nozzle ZG 1/4 P159 (stainless steel) |

| Control panel |

| Skip with bottom gate |

| Set of spare parts (paddles, armour, spokes) |

| Compressor Pole Position L25P |

| Compressor SB4/S-50.V47A |

| DIS inert materials dispenser for skip |

| Batching complex |

| Support for mixer |

| Cement Silo |

| RB-2 Big-bag discharger |

| Screw conveyor |

Twin-shaft concrete mixer consists of a stationary welded body with two horizontal shafts with spokes and scraper blades fixed on them. From 2015 the enforced spokes are made of cast steel and fixed to the shaft by knuckle mounting.

The shafts are joined by a synchronizing device to protect the drive. Mixture components are loaded directly into the mixer box which is protected from foreign particles by a protecting grid.

Is driven by an electric motor with power of 18.5 kW through the belt drive equipped by an outer cover and two renovated enforces reducing gears. Shafts spin rate – 36 rotations per minute.

Mixer box is coated from the inside by wear-resistant armor, flake type , made of cast iron 12 mm thick. The armour is changeable and fastened on screws. The armour consist of separate elements thus allows to change only worn out parts, it makes maintenance and repair works easier.

The ready-to-use mix is discharged through a window in the bottom of the body closed by pneumatically operated two-side gate.

When producing a semi-dry mix for a vibrating press, we recommend installing a ZG 1/4 nozzle for spraying water

- Производительность 30 м³\час

- 2 mixing shafts, 14 paddles

- Changeable cast iron wear-resistant armour 12 mm thick

- Mixer box is coated from the inside by wear-resistant armor, flake type .

- Броня сменная – износостойкий чугун 12 мм.

Technical Features

- Loading volume, l 750

- Ready-mix concrete volume, l 500

- Mortar volume, l 600

- Productivity, m³ 20...30

- The number of cycles per hour, when used in automatic lines 60

- Mixing time, seconds 10...60

- Aggregate size, mm max 70

- Shaft rotation speed, rot/min 32

- Supply voltage, V/Hz 380/50

- Total installed power, kW 18,5

- Sector gate, pneumatically operated

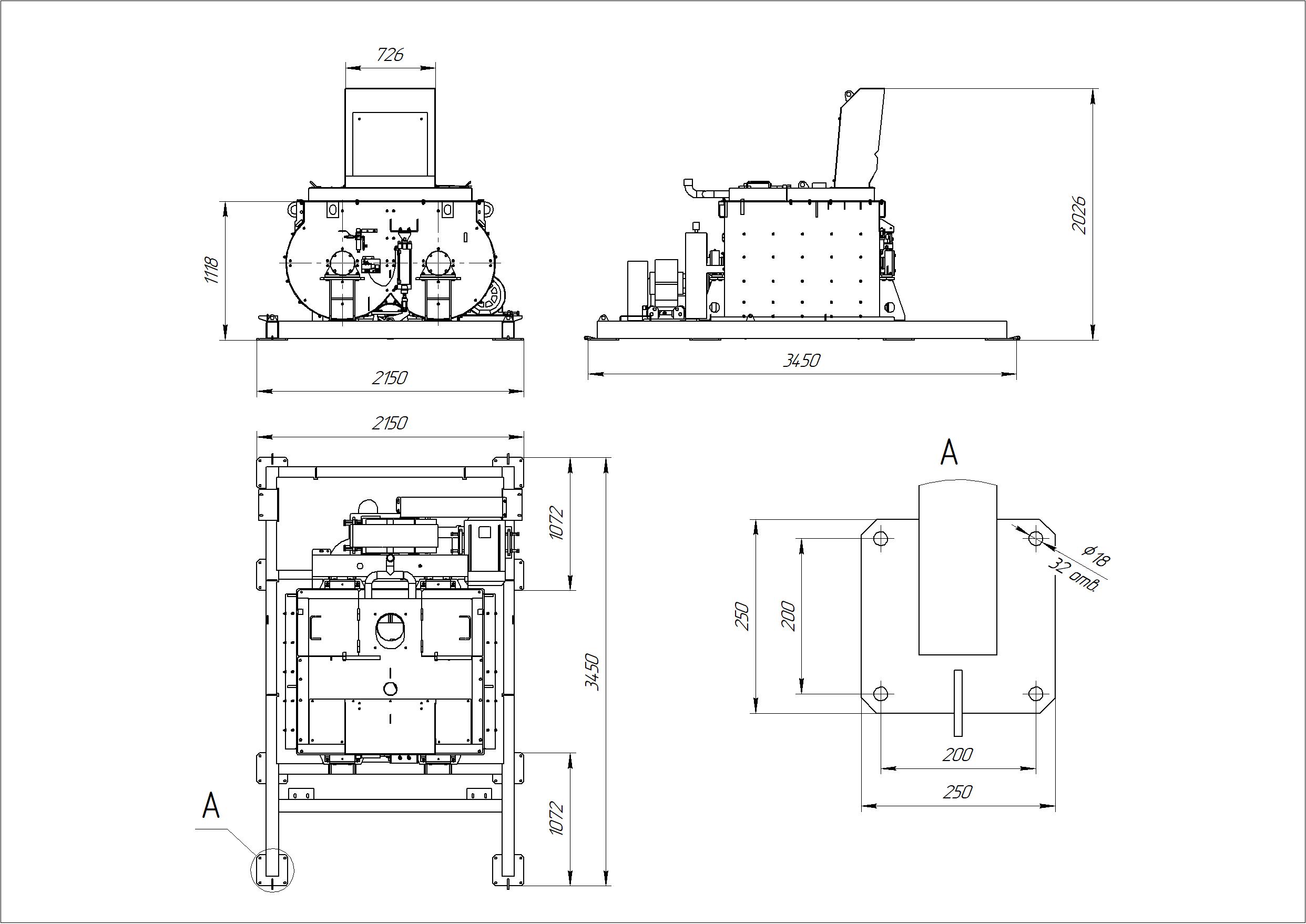

- Weight, kg 3,200

- Height, mm 1,130

- Width, mm 2,040

- Length, mm 1,575

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2026

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

г. Astana, prospekt Akžol, Zdanie 44, of. 32

e-mail: sales@zzbo.ru

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions