OPTIMAL 3.0 line

with BP-1G-300, LK 6-0.5 and BP-1G-100, LK-5-0.5

27 907 264 ₸

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| Vibropress OPTIMAL 3.0 |

| BP-1G-300 Concrete Mixer |

| Ленточный конвейер ЛК 6-0,5 |

| BP-1G-100 Concrete Mixer |

| LK 5-0,5 Belt Conveyor |

| The punch-matrix according to the customer's sketches |

| Vibrating table activation pedal (hand control) |

| Модуль для получения "теплоблоков" |

| Automatic remote control |

| technological pallets |

| Press splitting the PC-20 wall stones |

| BP-2G-185 Twin-shaft concrete mixer |

| BP-2G-375 Twin-Shaft Concrete Mixer |

| BP-2G-750 Twin-shaft concrete mixer |

| Concrete plant STANDARD-15 |

| MOBIL-20 Concrete Plant |

| Concrete plant COMPACT 20 |

Линия прессования на базе вибропресса Оптимал 3.0 создана чтобы исключить лишние ручные операции и человеческий фактор при производстве вибропрессованной продукции.

molding line can be operated in manual mode or in fully automatic mode. Of operational stages of the line:

- Loading of inert materials into the BP-2G-300 concrete mixer

- Подача готово смеси при помощи ленточного конвейера ЛК 6-0,5 в бункер накопитель вибропресса (загрузка серой смеси)

- Loading of inert materials into the BP-1G-100 concrete mixer

- Подача готово смеси при помощи ленточного конвейера ЛК 5-0,5 в бункер накопитель вибропресса (загрузка цветной смеси)

- Pallet feeding into the molding zone by a feed conveyor

- Vibrocompressed molding products on the pallet Technology

- Movement of pallets with molded products on a hydraulic lift

- Штабелирование изделий в стопки по 5 штук (на одном ряду 2 поддона), количество стопок зависит от высоты помещения

- Can be installed in rooms with a ceiling height of up to 3 meters

- high performance: 100 pallets finished products per hour of work

- Vibrating table 7.5 kW with a frequency converter «Schneider Electric»

- Forming zone size 800x400

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Corrosion protection of the two-component priming enamel (Germany) in the spray-drying chamber ATIS

- 2-year warranty

Technical Features

Quality

certificates

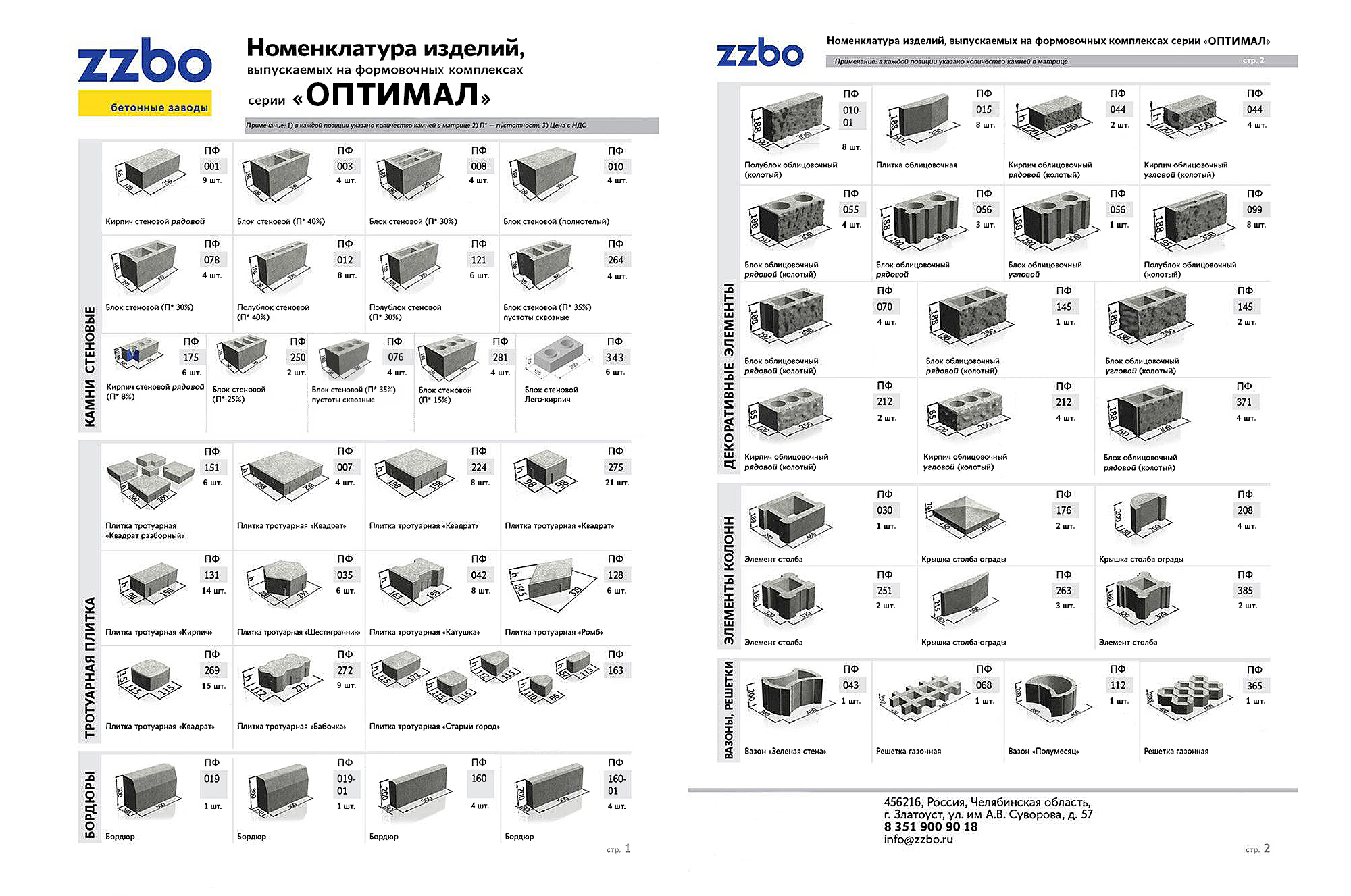

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

г. Astana, prospekt Akžol, Zdanie 44, of. 32

e-mail: sales@zzbo.ru

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions