Automatic line MAXIMAL

with stackers

78 698 704 ₸

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| Frame vibropress 4 and guide crosspiece |

| Vibrating table synchronized unbalance in an oil bath. Power 11 kW |

| Frequency converter |

| Hopper 1.2 cubic meters. meters with a hydraulic damper |

| The loading module mixture passive agitator, hydraulic actuator |

| Synchronizer guide matrix |

| Пуансонодержатель |

| synchronizer punch |

| Protective grid for safety |

| Hydroelectric power station 11.5 kW |

| feed module trays with conveyor and pallet magazine for 10 pieces |

| Roller conveyor to receive the finished product |

| Special brushes for removing burrs on the products |

| Technology pan - 1 piece |

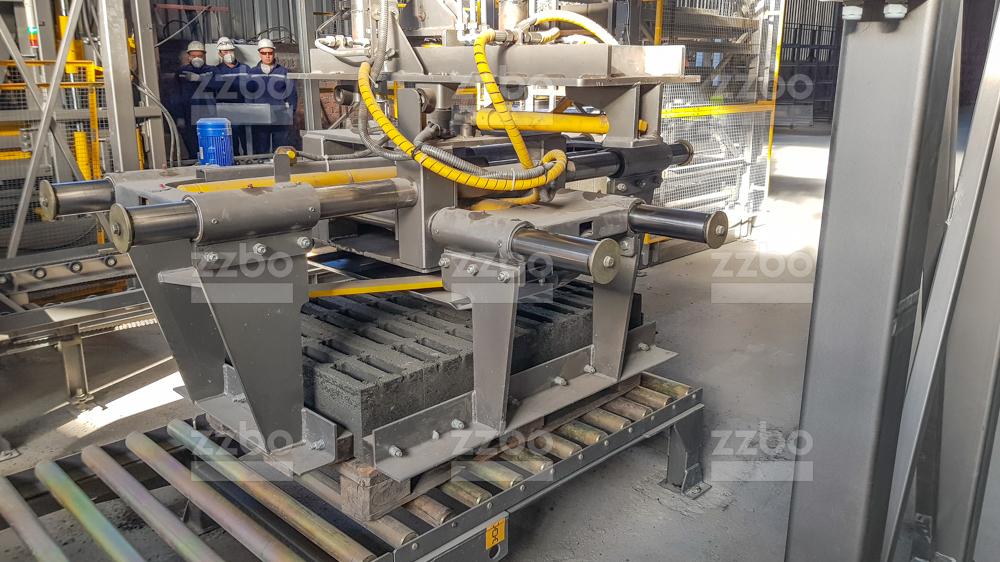

| Receiving roller lift the finished product |

| Stacker boot (collection trays of the molded article) |

| Pallet shelves with molded articles - 2 pieces |

| stacker discharge |

| The conveyor chain unloading truck |

| The system for cleaning of finished goods from the pallet and shipping pallet assembly |

| The system for the collection, cleaning, revolution and feeding a pallet process vibropress |

| Roller conveyor for cleaning the packed shipping pallets with finished products |

| Гидростанция мощностью 5,5 кВт, для линии разгрузки готовых изделий |

| Пульт автоматический по принципу "одна кнопка" для вибропресса МАКСИМАЛ |

| power cabinet |

| Passport to vibropress |

| Toolkit for the selection of concrete mixtures |

| The punch-matrix according to the customer's sketches |

| Загрузочный модуль "цветного слоя" |

| technological pallets |

| Автоматическая линия подачи и упаковки паллет |

| Pallet shelving with the molded article |

| Press splitting the PC-20 wall stones |

| BP-1G-100 Concrete Mixer |

| BP-2G-375 Twin-Shaft Concrete Mixer |

| BP-2G-750 Twin-shaft concrete mixer |

| LK 5-0,5 Belt Conveyor |

| Concrete plant STANDARD-15 |

| MOBIL-20 Concrete Plant |

| Concrete plant COMPACT 20 |

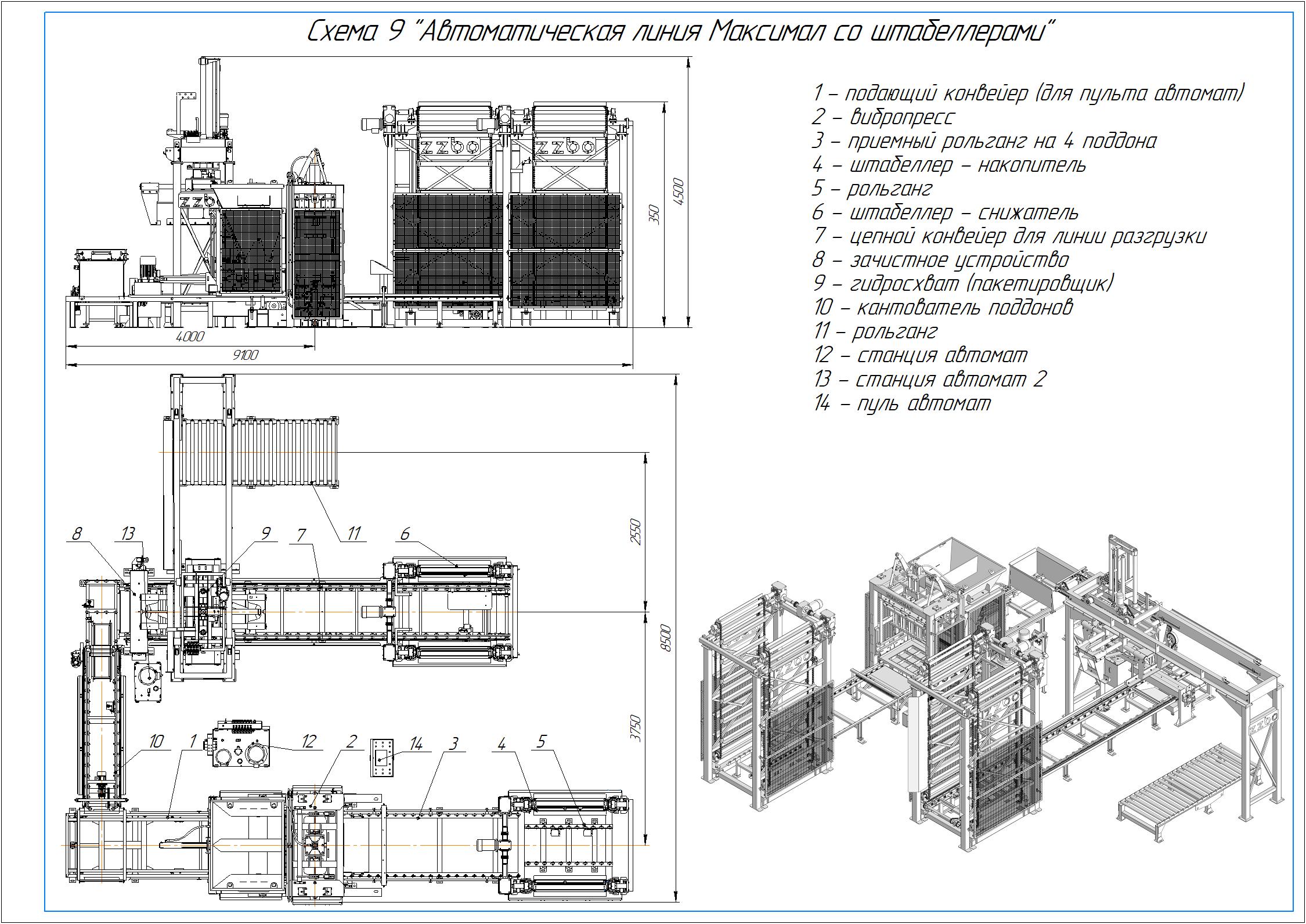

Line-based vibropress MAXIMUM - we have collected the maximum number of pripressovogo equipment to eliminate unnecessary manual operations and human factors in the production of vibropressed products.

Линия работает в полностью автоматическом режиме, оператор контролирует всю работу на сенсорном дисплее 10″. Пооперационные этапы работы линии:

- Molding Technology vibropressovannykh products on a pallet in an automatic mode,

- Movement of the pallet with the molded articles to the pallet stacker (2 pcs. On one floor)

- Штабелирование изделий в стопки по 2 штуки на одном уровне, количество стопок 5 штук, таким образом за один прием происходит снятие 10 технологических поддонов (20 дорожных бордюров, 60 стеновых блоков или 5 квадратных метров тротуарной плитки)

- Cleaning process pallet (the pallet 10 at a time) with the products in maturing this mass zone (steam chamber) with a forklift

- Trays with dried goods are fed into the discharge stacker for removal from the pallet technological

- Removing finished products gidroskhvatom and laying on the shipping pallet for cleaning truck to the warehouse

- Purification and supply, empty pallets in a pallet tilter revolution (for uniform wear and load), and further in the pallet storage device for re-cycle.

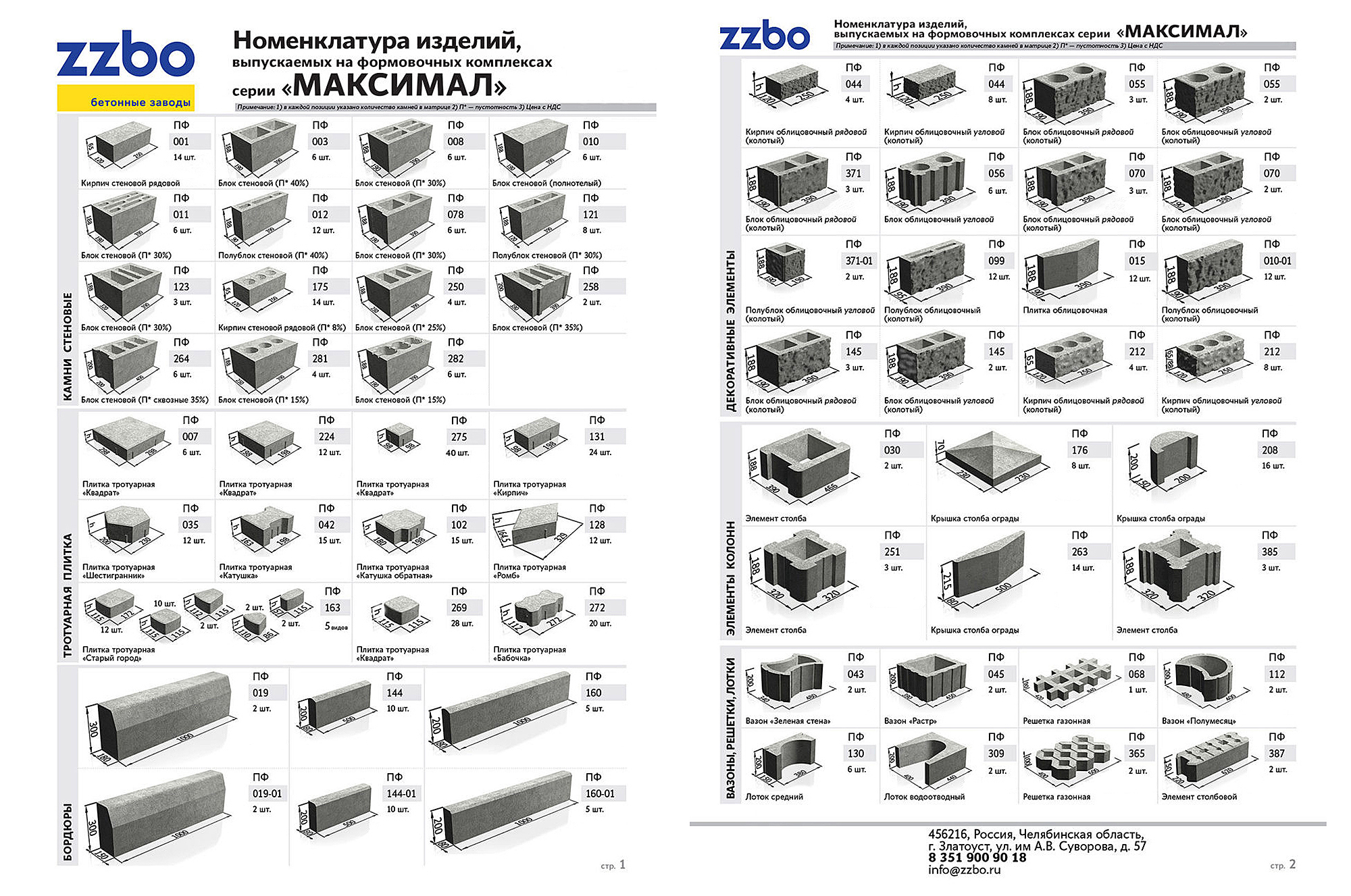

- The size of the molding 1000h600 zone - the highest performance in its class

- 11 kW vibrating table with frequency converter

- Ultra-compact line with the dimensions of 8800 x 9200

- Fully automatic block-making on the principle of "one button"

- Fully automatic operation of collecting trays with a molded article stacker

- Fully automatic operation for collecting the finished product from the pallet and packing it

- Remote control operation line operator with a touch screen 10 "

- The wide range of products

- Form 2 at the same time curb traffic in accordance with GOST

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection with a two-component primer-enamel in a painting and drying chamber

- 2-year warranty

Technical Features

- The size of the molding zone, mm x mm 1000 x 600

- The height of the molding zone, mm 50...300

- molding cycle s 30-60

- Power vibration table, kW 11

- Total installed power, kW 36

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

- The number of moldings per hour piece. 60...120

- Supply voltage, V/Hz 380/50

- Hopper capacity, cu. m 1,2

- Download matrix Boot box with passive turner, hydraulic actuator

- filing trays Store pallets, hydraulic actuator

- pallet storage system Stackers

- The system for the collection of finished products from pallets hydraulic cuber

- mode Auto

- Length, mm 7200

- Width, mm 8,800

- Height, mm 4,200

- Weight, kg 12000

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

г. Astana, prospekt Akžol, Zdanie 44, of. 32

e-mail: sales@zzbo.ru

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions