PAM 4.0 SCADA control panel

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| Automatic operation by pressing "one" button |

| Recipe storage database for concrete production |

| Programmable Logic Controller |

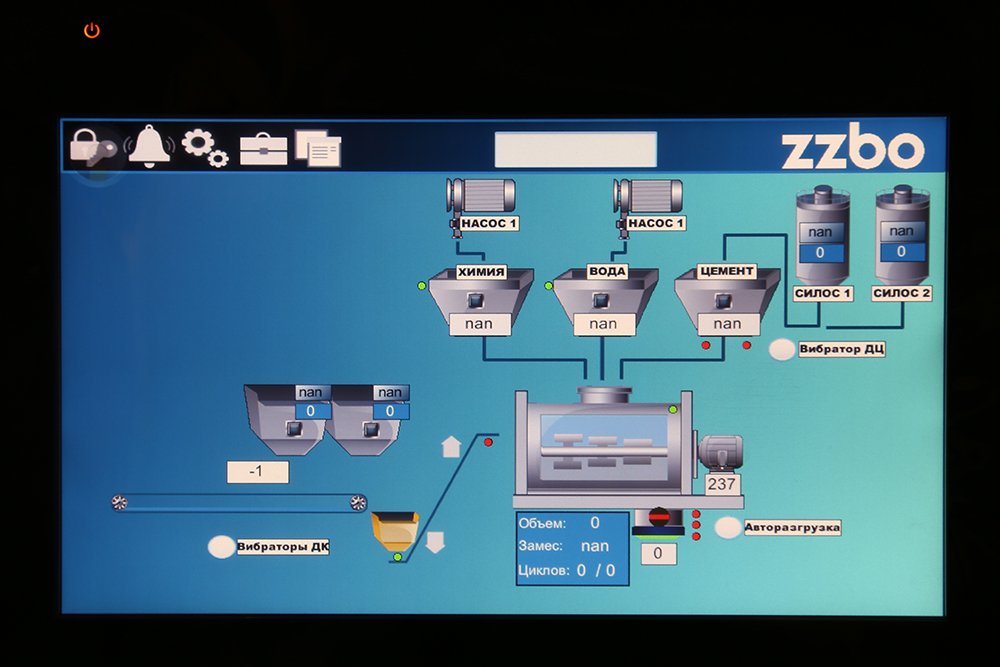

| Touch control panel, diagonal 10 inches, wide viewing angle, TFT-screen, 65,000 colors. |

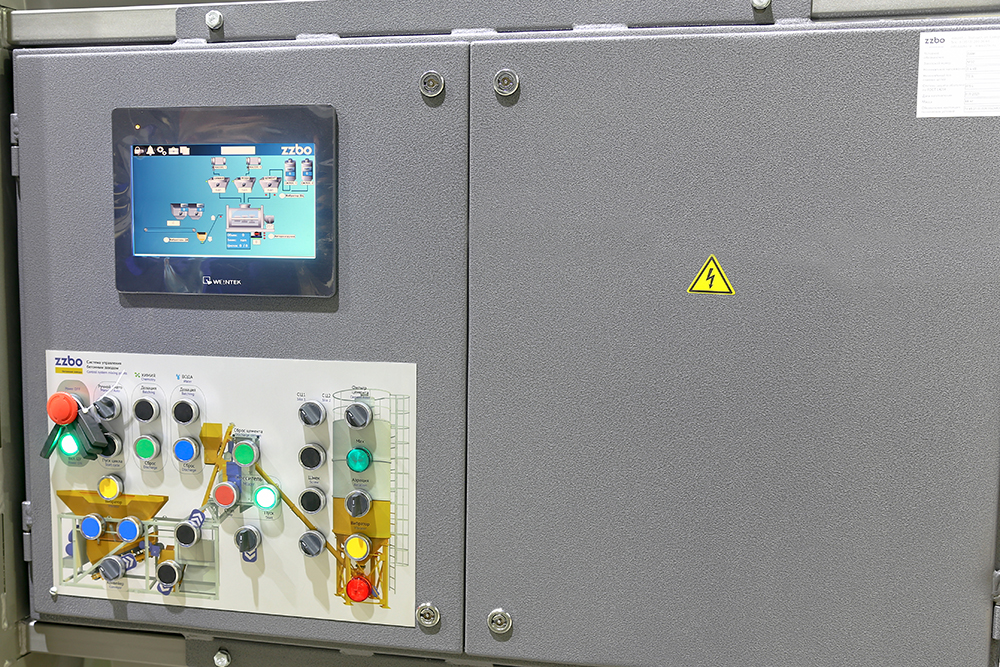

| Сontrol panel case protection - IP54 |

| Control, protection and switching equipment "Schneider Electric", "Omron", "ABB", "Siemens" |

| Manual control panel with ingress protection buttons on mimic panel |

| Set of diagrams and instruction manual |

| Software on our own SCADA system: accounting for material consumption and equipment operation, remote access and control of work |

Система управления проста в управлении благодаря графическому дисплею со встроенными клавишами. Для производства необходимо выбрать рецепт и количество бетона.

The PA control panel is designed to control the concrete plant in the following modes:

- Ручной режим. Работа при помощи графического пульта управления с интуивной панелью и отображение работы на сенсорной графической панели

- Auto. Work using a graphic touch terminal. The operator needs to select the recipe and the amount of concrete required, press the “Start” button

- Work with PC (optional). Work using a personal computer (monoblock) installed at the workplace. Selection (task) of the required recipe and the required number of batches. In addition to the required technological information, the computer screen displays: - messages about malfunctions and errors of the control system - information necessary to account for the consumption of materials (water, cement, electricity, chemical additives) and finished products. Information can be issued for any period of time - year, month, week, day. – information necessary to control the work of personnel (fixing actions, error control, entering incorrect recipes)

In auto and manual mode using the remote control comes with the following equipment:

- Batching complexSix gates and six vibrators aggregate (two valves per product), the conveyor-feeder feeding aggregate in the skip, including reverse

- Concrete mixer: skip for supplying aggregate to the concrete mixer (two-speed option, lowering twice as fast as lifting), propulsion motor and pneumatic unloading valve

- Cement auger into DC dispenser

- cement dispenser: Valve unloading cement dispenser

- Cement silo: solenoid valve for air aspiration of cement unloading, vibrator control, visual control of the upper and lower position of cement in the silo

- water dispenser: Pump feeding water into the dispenser and pump draining water from the dispenser

- Dosing of chemical additives: Pump feeding the chemical additives into the dispenser and drain pump chemical additives from the dispenser.

- Automatic operation of concrete production

- The controller and touch graphical control panel

- Accessories Schneider Electric, Omron, Siemens

- Graphic mimic diagram on the operator control panel

- Base for recording and storing recipes

- Materials accounting

- Working with the graphic panel: input commands, recipes, status monitoring, error display

- Possibility of connecting Scada system to control the plant from a PC

Technical Features

- Power supply 3-phase with neutral to earth, in 400

- Degree of protection against dust and moisture IP 54

- Temperature the product, +5...+45

- Swipe input mass signal in 0...2,5

- The total error of measurement of weight,% 0,1

- Supply water dispenser control signals himdob-ki and cement, in 0...24

- Output current control signal feeders, not more than A 2

- mixer motors, pipeline management, vibrators, The 400

- flap valves Control valves and mixer DK, The 220

- Weight, kg 90

- Height, mm 1,100

- Width, mm 900

- Depth mm 440

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

г. Astana, prospekt Akžol, Zdanie 44, of. 32

e-mail: sales@zzbo.ru

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions