Vibropress OPTIMAL Mini with module

13 158 787 ₸

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| Rama vibropressa 2 napravlâûŝimi and traversoj |

| Vibrating table synchronized unbalance in an oil bath. Power 7.5 kW |

| Frequency converter |

| Loading hopper 0.8 cubic meters meter with hydraulic gate |

| The loading module mixture passive agitator hydraulic drive (for sulfur mixture) |

| Synchronizer guide matrix |

| Puansonoderzhatel with a vibrator |

| synchronizer punch |

| Protective grid for safety |

| 4 kW hydro power plant |

| semi-automatic control unit |

| Roller table for receiving pallets with finished products for 1 pallet |

| Technology pan - 1 piece |

| Passport to vibropress |

| Toolkit for the selection of concrete mixtures |

| The punch-matrix according to the customer's sketches |

| feed module trays |

| Roller conveyor and rack for the finished product |

| Vibrating table activation pedal (hand control) |

| Gidropodʺemnik |

| Модуль для получения "теплоблоков" |

| Hoist (accumulator) chain |

| Automatic remote control |

| technological pallets |

| Press splitting the PC-20 wall stones |

| BP-1G-100 Concrete Mixer |

| BP-2G-185 Twin-shaft concrete mixer |

| BP-2G-375 Twin-Shaft Concrete Mixer |

| BP-2G-750 Twin-shaft concrete mixer |

| LK 5-0,5 Belt Conveyor |

| Concrete plant STANDARD-15 |

| MOBIL-20 Concrete Plant |

| Concrete plant COMPACT 20 |

Universal vibrating press II size group with the size of the molding zone 800 x 400. Ideal for industries with their own concrete mixers or concrete plants.

The purpose of the vibropress "Optimal" is to obtain a variety of building products from rigid concrete mixes by the method of semi-dry vibrocompression. The composition of the technological equipment is determined by the customer's requirements: the required productivity, placement possibilities, supply volumes of raw materials and can be gradually increased from the minimum (vibropress + mixer) to a fully equipped plant, with the implementation of weight dosing of inert materials and automatic operation.

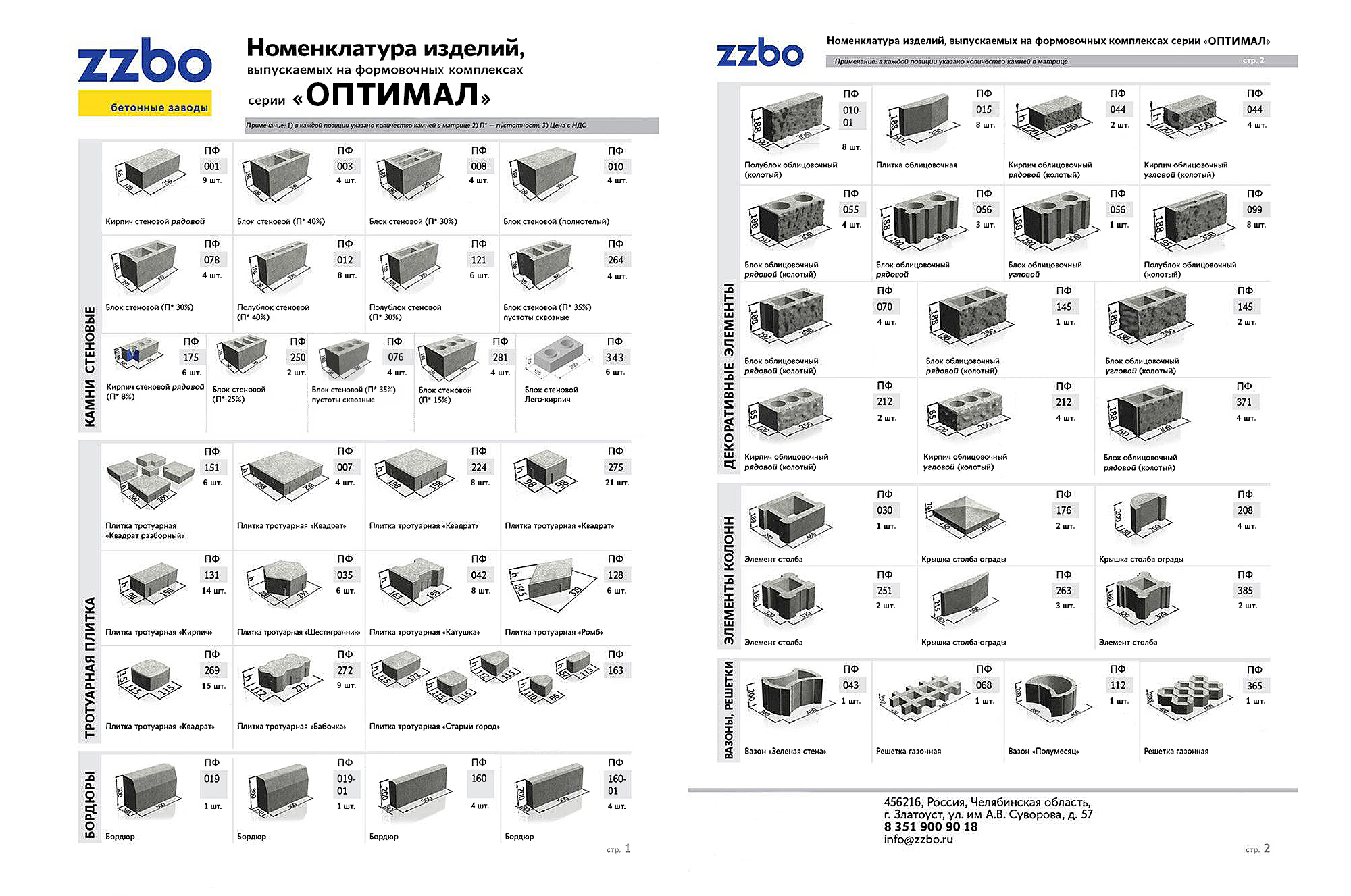

Sets of interchangeable shaping equipment (punch-matrix) make it possible to manufacture a wide variety of building products for a wide range of applications: those used in new construction, restoration of old structures and landscaping of adjacent territories, creating original architectural appearances of buildings. The range of products is constantly updated with new samples, while the desires of the consumer are limited practically only by the area of the molding zone 800 x 400 mm and the height of products 50 ... 250 mm.

"Optimal" can be operated and stored in closed rooms or under a canopy at an ambient temperature of + 5⁰ to + 45⁰ C. The minimum area required to accommodate the Optimal molding block, raw materials and finished products warehouses is 250 m2, the minimum hook lifting height lifting equipment 3.5 m. The timing of the commissioning of the forming block "Optimal" with the receipt of trial products by the manufacturer's commissioning team is 3-8 working days.

К эксплуатации оборудования допускаются лица, прошедшие обучение на право работы, технического обслуживания и ремонта, знакомые с правилами техники безопасности. Исходным материалом для приготовления смеси служат заполнитель, вяжущее и вода. В качестве заполнителя могут использоваться песок, отсевы щебеночного производства, керамзит, шлаки, золы, опилки и любые другие сыпучие материалы, способные после смешивания с вяжущим приобретать и сохранять заданную форму. В качестве вяжущего применяется цемент. При использовании смеси на основе цемента, готовые изделия подвергаются вылеживанию от 1-х (при температуре +15⁰…+45⁰ С) до 2-х (при температуре +5⁰…+10⁰ С) суток, после чего они приобретают прочность, достаточную для складирования и транспортировки. 100% прочности изделия приобретают через 28 суток при температуре вылеживания 20⁰ С.

При наличии у потребителя камеры термо-влажностной обработки (ТВО) изделия могут подвергаться тепловой обработке в течение 6…8 часов при температуре не менее + 50⁰…75⁰ C. и влажности 80%. В этом случае после остывания и высыхания они приобретают 60…80% марочной прочности.

The special design and high precision of manufacturing matrices provide high geometric accuracy and beautiful appearance of products obtained on the Optimal forming block. Thanks to this, when building buildings from wall stones, it is possible to speed up the masonry process while saving mortar and get even walls with thin seams, and when using other products obtained in construction, beautifully landscape the territory. During the operation of the Optimal block, the products are pressed out of the forming equipment of the vibropress onto special pallets. Pallets are designed for keeping molded raw products in the process of their natural hardening or steaming.

The set of delivery of the complex includes 1 pallet and 1 rack, intended for the manufacture of an experimental batch of products when the complex is launched at the consumer. For the operation of the complex during single-shift operation, the consumer must manufacture on his own from 500 pallets (the number of pallets is determined by the quality of the organization of production at the consumer and the presence of a HBO chamber, less pallets are required when steaming products, more when natural hardening). In addition, the consumer must produce from 100 racks for storing pallets with products. The number of racks is determined by the number of pallets: five plywood pallets are placed on one rack.

- Forming zone size 800x400

- Upgraded synchronized vibrating table with a power of 7.5 kW, with a frequency converter

- Semi-automatic mode vibropress

- Automatic feeding the mixture to the matrix

- The wide range of products

- High quality of produced materials, all products comply with GOST.

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection with two-component primer-enamel in the ATIS painting and drying booth

- 2-year warranty

Technical Features

- The size of the molding zone, mm x mm 800 x 400

- The height of the molding zone, mm 50...250

- molding cycle s 30...80

- Power vibration table, kW 7.5

- Installed power, kW 11,5

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

- The number of moldings per hour piece. 60…120

- Supply voltage, V/Hz 380/50

- Hopper capacity, cu. m. 0,8

- Download matrix Boot box with passive turner, hydraulic actuator

- pallet storage system Rack

- mode semi-automatic

- Length, mm 2,650

- Width, mm 3100

- Height, mm 2340

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

г. Astana, prospekt Akžol, Zdanie 44, of. 32

e-mail: sales@zzbo.ru

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions