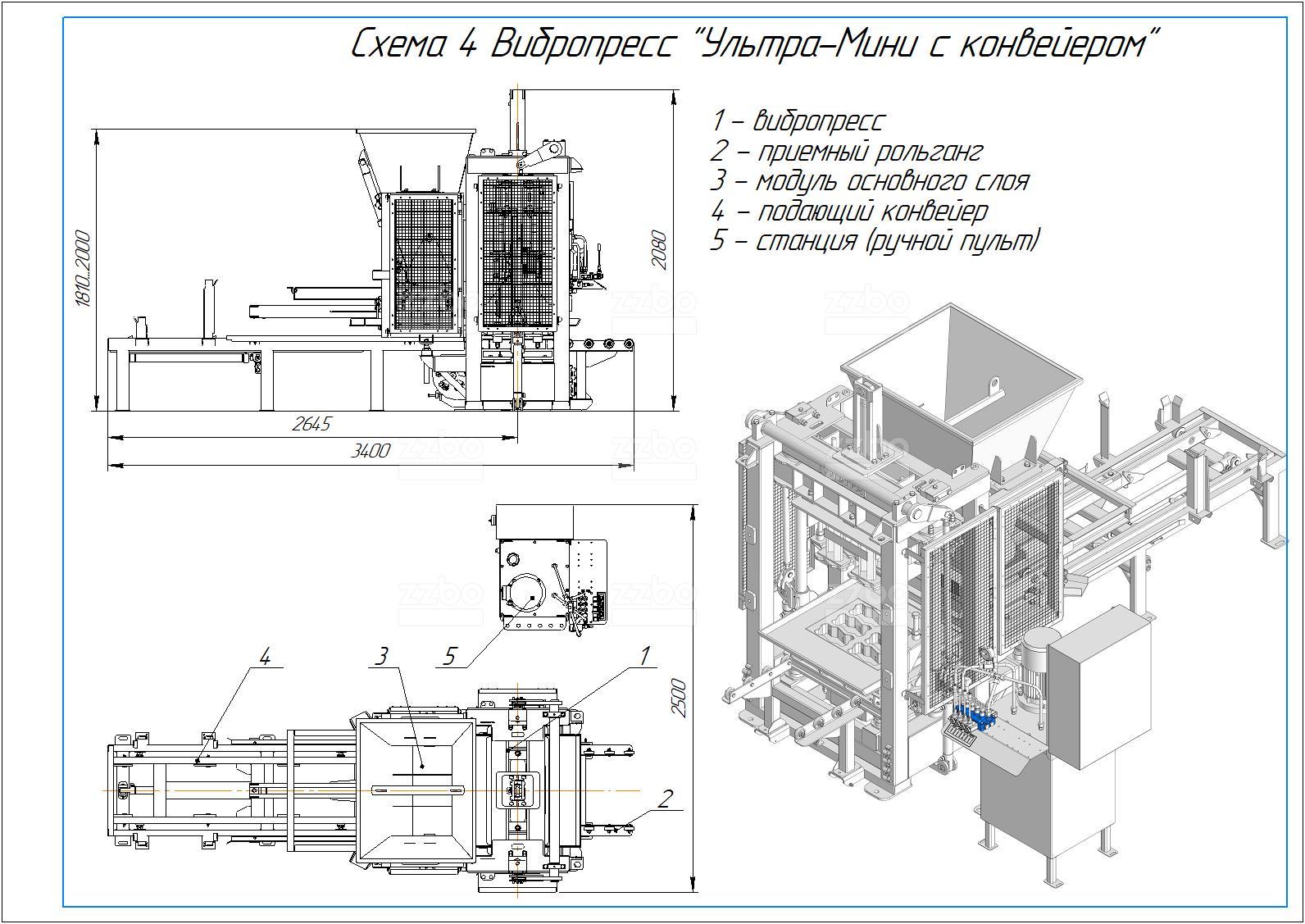

Vibropress ULTRA Mini with conveyor

10 497 535 ₸

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| Rama vibropressa 2 napravlâûŝimi and traversoj |

| Vibrating table synchronized unbalance in an oil bath. 5.5 kW |

| Frequency converter |

| The hopper volume of 0.4 cubic meters. meters, with a hydraulic damper |

| The loading module mixture passive agitator. hydraulic drive |

| Synchronizer guide matrix |

| Removable protective grid for safety |

| 4 kW hydro power plant |

| semi-automatic control unit |

| feed module trays with conveyor and pallet magazine for 10 pieces |

| Roller conveyor for receiving pallets with finished products |

| Technology pan - 1 piece |

| Passport to vibropress |

| Toolkit for the selection of concrete mixtures |

| The punch-matrix according to the customer's sketches |

| Vibrating table activation pedal (hand control) |

| Gidropodʺemnik |

| Hoist (accumulator) chain |

| Загрузочный модуль, для загрузки "цветного слоя" |

| Automatic remote control |

| Press splitting the PC-20 wall stones |

| BP-1G-300 Concrete Mixer |

| BP-2G-375 Twin-Shaft Concrete Mixer |

| LK 5-0,5 Belt Conveyor |

| Concrete plant STANDARD-15 |

| MOBIL-20 Concrete Plant |

| Concrete plant COMPACT 20 |

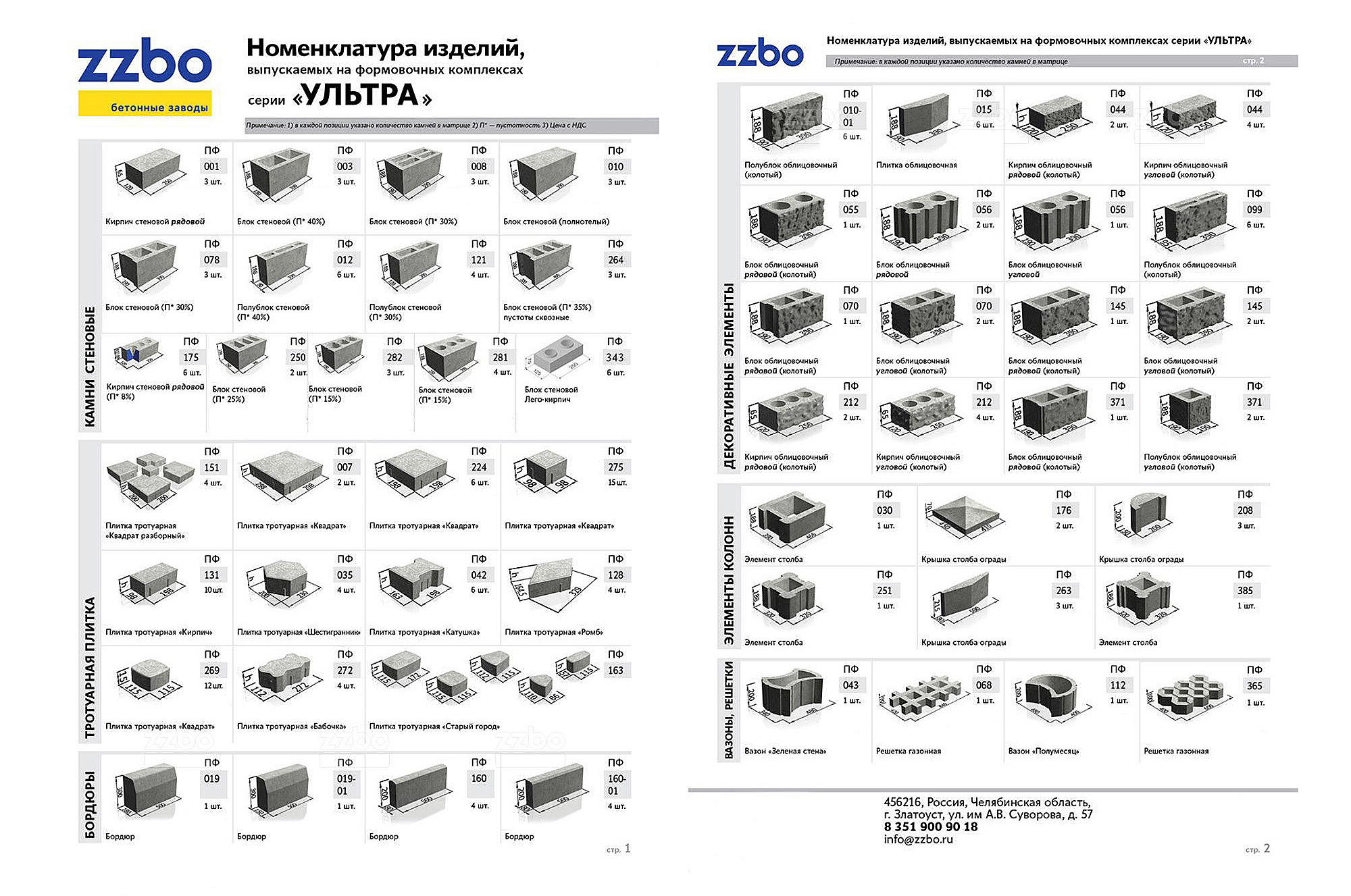

Stationary compact vibropress ULTRA series is designed for the production of small concrete products by semi-dry vibro: wall stone, paving slabs, garden edging, bricks and so on.

This model of the ULTRA series vibropress is equipped with: a module for supplying a concrete mix to a matrix, a module for automatic feeding of pallets.

К эксплуатации оборудования допускаются лица, прошедшие обучение на право работы, технического обслуживания и ремонта, знакомые с правилами техники безопасности. Исходным материалом для приготовления смеси служат заполнитель, вяжущее и вода. В качестве заполнителя могут использоваться песок, отсевы щебеночного производства, керамзит, шлаки, золы, опилки и любые другие сыпучие материалы, способные после смешивания с вяжущим приобретать и сохранять заданную форму. В качестве вяжущего применяется цемент.

При использовании смеси на основе цемента, готовые изделия подвергаются вылеживанию от 1-х (при температуре +15⁰…+45⁰ С) до 2-х (при температуре +5⁰…+10⁰ С) суток, после чего они приобретают прочность, достаточную для складирования и транспортировки. 100% прочности изделия приобретают через 28 суток при температуре вылеживания 20⁰ С.

При наличии у потребителя камеры термо-влажностной обработки (ТВО) изделия могут подвергаться тепловой обработке в течение 6…8 часов при температуре не менее + 50⁰…75⁰ C. и влажности 80%. В этом случае после остывания и высыхания они приобретают 60…80% марочной прочности.

Transition to production of another type of product per hour - by changing the punch-matrix.

В процессе работы изделия выпрессовываются из формообразующей оснастки вибропресса на технологические поддоны. Поддоны предназначены для вылеживания отформованных сырых изделий в процессе их естественного твердения или пропаривания.

The operation of the ULTRA Mini vibropress with a conveyor begins with the loading of technological pallets into the receiving magazine, the capacity of the pallet magazine is 10 pieces. Next, we fill the vibropress hopper with ready-made concrete mix, the hopper with an increased volume of 0.4 cubic meters. meters. We feed the pallets on the vibrating table with a conveyor, power of 5.5 kW with a frequency converter. Using a loading box with a passive agitator, we fill the matrix with a concrete mix. Next, the punch is lowered and the process of vibrocompression takes place. After that, the molded products are fed by the pallet conveyor to the receiving roller table.

molding cycle is repeated articles.

- attractive price

- The wide range of products

- Vibrating table with a power of 5.5 kW with a frequency converter

- Size 600x400 molding zone

- Automatic feeding trays

- Automatic feeding the mixture to the matrix

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection with a two-component primer-enamel in a painting and drying chamber

- 2-year warranty

Technical Features

- The size of the molding zone, mm x mm 400 x 600

- The height of the molding zone, mm 50...200

- Performance of masonry 390h190h188, pieces per hour 135...270

- Performance paving tiles 100h200, pcs h 450...900

- molding cycle s 40...80

- The number of moldings per hour piece. 45…90

- Power vibration table, kW 5.5

- Total installed power, kW 9,5

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

- Supply voltage, V/Hz 380/50

- Download matrix Boot box with passive turner, hydraulic actuator

- filing trays Store pallets, hydraulic actuator

- mode semi-automatic

- Height, mm 2080

- Width, mm 2,500

- Length, mm 3,400

- Weight, kg 1730

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2026

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

г. Astana, prospekt Akžol, Zdanie 44, of. 32

e-mail: sales@zzbo.ru

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions