The mixers the mixing of basic components necessary for the production of concrete - water, cement, sand, gravel, cement and additives, which give certain specific properties of the concrete mix.

Naturally, the main requirements that apply to the mixer, are:

- The high degree of homogeneity of the resulting concrete mix that determines the quality of the final product;

- High-performance, end up affecting the profitability of the use of this type of mixer.

Leading manufacturers of concrete mixing equipment oriented towards the production of mixers two fundamentally different principles of the collapse of the concrete mixture while stirring:

- Gravity type mixers, the mixture in containers which rotates with the drum, and fall on top of the housing under the force of gravity;

- type forced mixers, in which the housing is stationary and the mixing is performed by special working blades.

CAMOZZI pneumatic gate - two-side

In turn, structurally forced mixers are divided into two types:

- Mixers with horizontal shafts, the rotational axes of which are horizontal;

- Concrete mixers with vertically mounted shafts.

The main advantages of compulsory mixer with horizontal shaft

- In the mixer with a vertical axis of rotation of the shaft with paddles is probable bundle concrete components due to differences in specific gravities, which may be less than that of water.

- Concrete mixers with horizontal shafts are capable of producing concrete mixtures in a wide range of specified density and mobility;

- The quality of the concrete mix with larger particles, fillers mentioned in mixers with a horizontal shaft.

- Обслуживание и профилактические работы более просты и удобны для горизонтально расположенных валов.

- Потребление электроэнергии бетоносмесителями с горизонтальными валами ниже, чем у аналогов той же производительности с вертикальными валами.

In accordance with these and other additional factors ZZBO focuses on the production of concrete mixers with horizontal shafts.

The range of twin-shaft mixers ZZBO

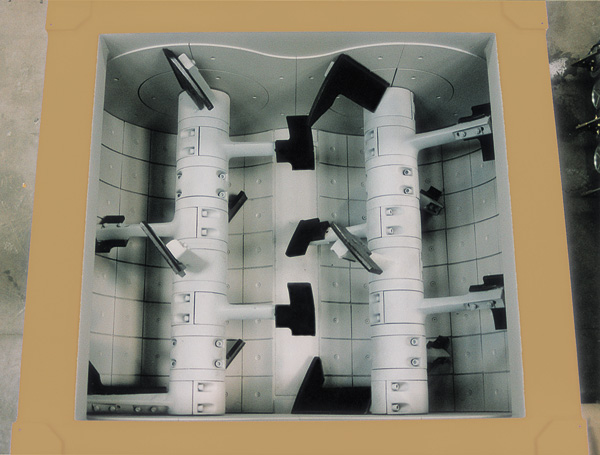

ЗЗБО производит двухвальные бетоносмесители, конструктивно представленные горизонтально-цилиндрическим корпусом , на торцах которого расположены подшипниковые узлы. На двух горизонтально размещенных валах закреплены от 10 до 16 рабочих лопастей, которые при вращении навстречу друг другу создают эффект подбрасывания бетонной смеси с одновременным ее разрезанием. Такая турбулентность позитивно отражается на гомогенности состава бетонной смеси.

ZZBO produces twin-shaft mixers in two versions:

1. With the skip hoist, which includes models:

- BP-2G-185s;

- BP-2G-375s;

- BP-2G-750s;

- BP-2G-1200s;

- BP-2G-1500s.

2. Without skip:

- BP-2G-185;

- BP-2G-375;

- BP-2G-750;

- BP-2G-1200;

- BP-2G-1500;

- BP-2G-2250th

Бетоносмесители ЗЗБО отличаются высокой надежностью в работе и обладают высоким ремонтопригодным потенциалом, поскольку броня и лопасти смонтированы в сменном варианте, допускающим их замену по мере абразивного износа.

CAMOZZI pneumatic gate - two-side