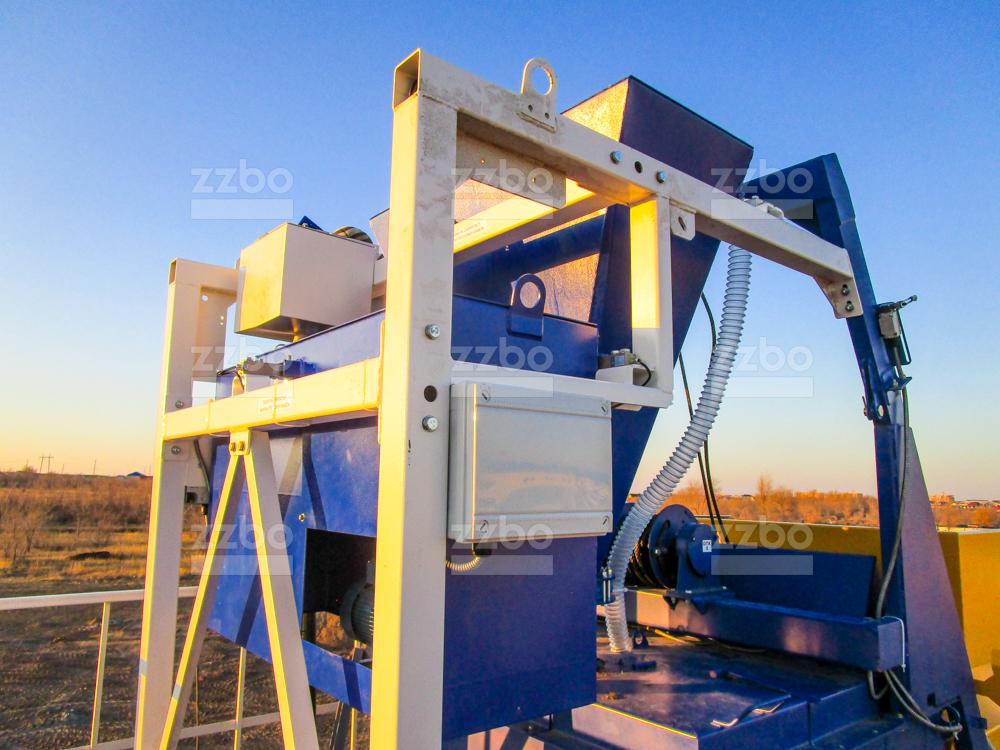

MIXER-45 Concrete Plant

27 343 703 ₸

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

4 486 104 ₸

- Mounting frame, mobile. Installation without foundation

- Design enhanced, adapted for the discharge of concrete on the height of 4000 mm

- mixer platform with supporting structures

- Ladders for equipment maintenance

- Fence along the perimeter

- Staircase with handrails

- Funnel for unloading concrete with rubber guide

- Skip ways - rails

- Fastening construction for pipes and electric cables

- Coating: shotblasting, double coloration with drying chamber

- Reinforced and protected operator's cab installation place

15 182 300 ₸

- Mounting frame. Installation without foundation

- 2 hoppers 12 cu m each (or 4 hoppers 6 cu m each - optionally)

- Preparation under registers installation for heating inert materials

- Pneumatic valves - 4 pieces

- Pneumatic dampers - 4 pieces

- Filter regulator - 1 piece

- Vibrators MVE 3003 - 4 pieces

- Inert materials belt conveyor (dosage - 0-1500 kg). Belt speed - 1.6 m/sec

- 7.5 kW lined motorized conveyor drum with smooth-start system (when purchased with control panel)

- Drum tension station

- Load cells SBA-2T 2 tons - 4 pieces

- CAS connecting box

- Signal amplifier - weight sensor

- Passport to complex metering and purchased products

5 220 264 ₸

- Software on your own SCADA system complete with a monoblock: accounting for the consumption of materials and equipment operation, remote access and control over the work in the local network

- Automatic operation by pressing "one" button

- Recipe storage database for concrete production

- Programmable Logic Controller

- Сontrol panel case protection - IP54

- Power cabinet case protection - IP54

- Control, protective and switching equipment "Omron", "Siemens"

- Set of diagrams and instruction manual

4 055 912 ₸

- Mounting frame (powder coating). Weight - 150 kg

- Cement dispenser, a dosage - 300 kg (powder coating):

- Two inlet nozzles for screw conveyors (one is covered by a cap)

- Connecting outer sheath with collar clamps

- Overpressure system

- Unloading disc damper ∅200

- Strain gauges - 3 pcs.

- Signal amplifier - weight sensor

- Pneumatic distributors - 3 pcs.

- Vibrator MVE 300/3 - 1 pc.

- Water dispenser for 150 liters (powder coating):

- Strain gauges - 3 pcs.

- Water and chemical agents multipoint injection system

- Water dump pump

- Signal amplifier - weight sensor

- Сhemical additives dispenser, dosage - 20 liters, made of stainless steel:

- Strain gauges - 1 pc.

- CAMOZZI d 50 discharging ball pneumatic damper

- Signal amplifier - weight sensor

2 402 764 ₸

- Hardware for assembly RBU: metering complex overpass screw silage

- Hardware, accessories

- Wire for screw fixing

- Kit for connecting the database (pnevmotruba, sleeves, bends, RVC 51-70 clamps, duct PVC-5-C-60)

- Limit switch for the database

- Kit vodopodvedeniya (pipe bends, sleeves, T-joints, anchor bolts, brackets)

- Kit RBU pneumatic (air tubing, pnevmotruba, fittings, hardware)

- Set of cables

- Couplings (5 titles)

- compactor

- Acid sealant TempPlus

- Power and control cables, protected by metal hose (in mobile plants they are laid in frame)

- Set of locking sensors and executing mechanisms position sensors (skip, mixer's gate, etc.)

1 080 632 ₸

- Operator's cabin. Sheathed by zinc-coated painted profiled sheeting, finishing accessories, moisture protecting impregnation

- Frame protected against corrosion, 60 mm thick heat insulation

- Sound insulation, protection against rain

- One window (PVC, double glazing), insulated door with lock

- Lighting

- Slinging loops

- Weight - 180 kg

4 160 240 ₸

- Silo tank (V = 28 m3)

- Mounting frame

- Stairs

- Cover protection enclosure

- Loading pipe d 102 with connection lock

- Connecting flanges for installation cement filter emergency valve, level sensors, aeration and vibrator

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection is made with a two-component primer-enamel PentriProtect PUR 700 based on polyurethane-acrylic resin in the ATIS spray booth

- Machinery certificate

253 736 ₸

- The pump Calpeda MXH 202E assembled for chemical supply. additives

- Capacity - 80 liters/min

- Power - 0.33 kW

- Weight - 6.9 kg with packaging

- Machinery certificate

- Фильтр цемента с виброочисткой FCS-24 NEON в сборе

- Filter elements - 14 pieces

- Корпус из нержавеющей легированной стали

- Vibrator - cartridge vibration cleaning system

- Silage setting ring

- Lid

- Machinery certificate

524 860 ₸

- RMK-2M washer

- Mounting frame

- Service ladder

- Protective cover of precipitation

- Dispenser capacity 2.35 tons of cement

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection is made with a two-component primer-enamel PentriProtect PUR 700 based on polyurethane-acrylic resin in the ATIS spray booth

- Knife material: high quality tool steel

- Machinery certificate

129 444 ₸

- Emergency pressure relief valve PV273 assy

- Adjusting ring

- Operational documentation

68 264 ₸

- Cement level sensor G2 1/2 220V assy in a package

- Adjusting ring

- Operational documentation

113 344 ₸

- Butterfly valve DN300

- Handle for gate control

- Operational documentation

6 631 268 ₸

- Silo Tank (V = 50 m3): cover - 4 sectors, cylindrical section - 12 sectors, large cone - 4 sectors, small cone

- Mounting frame

- Stairs

- Cover protection enclosure - 11 sectors

- Loading pipe d 102 with connection lock

- Inspection hatch (Viewing window for inspection and cleaning of the cone)

- Connecting flanges for installation cement filter emergency valve, level sensors, aeration and vibrator

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection is made with a two-component primer-enamel PentriProtect PUR 700 based on polyurethane-acrylic resin in the ATIS spray booth

- Frame for transportation

- Hardware for the assembly of a silo

- Polyurethane sealant Soudaflex FC 40 gray 600ml - 9 tubes

- Machinery certificate

2 425 304 ₸

- Auger assembly

- Pipe Diameter 219 mm, length of the pipe 10 000 mm

- Drive: motor-reducer. Power 11 kW

- Inspection window for cleaning and maintenance

- Operational documentation

Concrete plant "MIXER-45" comes in automatic mode on the principle of "one button". The operator must select the brand of the planned concrete mix (M50 ... M500) and his number to download the pre-mixture directly into the truck mixer, press the start cycle.

CAMOZZI pneumatic gate - two-side

Для производства смеси бетона, и выгрузки ее напрямую в автобетоносмеситель. Перемешивание происходит в автобетоносмесителе во время доставки бетона

Mixing concrete directly to the concrete mixer trucks during delivery of concrete to the subject, for good mixing is sufficient for about 20 minutes.

Пульт управления ПА2.0 располагается во встроенной в раму операторской кабине. Кабина оснащена двумя смотровыми окнами и дверью.

Весь завод смонтирован на раме, которая устанавливается на ровной площадке.

For concrete plant MIXER-45 It does not require the production of foundation and skip pit.

For storage and dosing inert: metering complex DC-24. Inert stored in silos, hoppers 4 number 6 cc. meter Total capacity is 24 cu m. . Под бункерами установлен ленточный конвейер-дозатор, на котором происходит дозирование компонентов, компоненты подаются из бункеров посредством открытия пневмозатворов “Camozzi” (Италия). При наборе необходимой дозы инертных, включается конвейер и инертные подаются в скип, который поднимает компоненты вверх и выгружает напрямую в автобетоносмеситель через приемную воронку.

The cement is stored in a special warehouse - cement silo (not included in the basic package). Silos for cement must be selected the rate of two daily stock performance. For feeding cement from a cement silo dispenser must acquire the correct length screw.

Cement silos, silo piping and augers are always in stock at the ZZBO warehouse in Zlatoust!

Cement and water are dosed via dosing block DB-30, which is mounted on top of the trestles, directly over the receiving hopper.

Using cement is fed into the screw cement batcher (maximum weighing capacity of 300 kg), which dosing occurs as necessary to reset cement truck mixer directly.

Water is dosed via the dispenser water (weighing 200 kg maximum dose).

Основное перемешивание всех компонентов смеси и получение необходимой гомогенности смеси происходит в автобетоносмесители во время доставки бетона до объекта.

- Capacity 45 cu m per hour

- No foundation or skip pit needed

- Automatic control system - "single button" principle

- Transportation 1 euro trailer or 40 foot container

- Quick deployment and start-up - within one working day

Technical Features

- Productivity, cube. m h 35...45

- Автоматический режим по принципу "одна кнопка"

- Work directly in the truck mixer

- Bunker (number of x amount of cubic meters) 4x6 = 24

- Silo capacity (optional), tons from 22

- Pneumatic equipment (Italy) CAMOZZI

- ABAC Pole Position L20P Compressor (Italy) ABAC

- Design summer

- Submission inert mixer truck skip

- Total power, kW 20,6

- Sector gate, pneumatic control

- Weight, kg 6,200

- Height, mm 7,300

- Width, mm 3310

- Length, mm 11,710

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning team

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

Mr. Astana, prospekt Akzhol, building 44, of. 32

e-mail: sales@zzbo.ru

Artem Kononovich

Director of the branch in Kazakhstan

Phone: +7 (7172) 760-141

e-mail: sales@zzbo.kz

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions