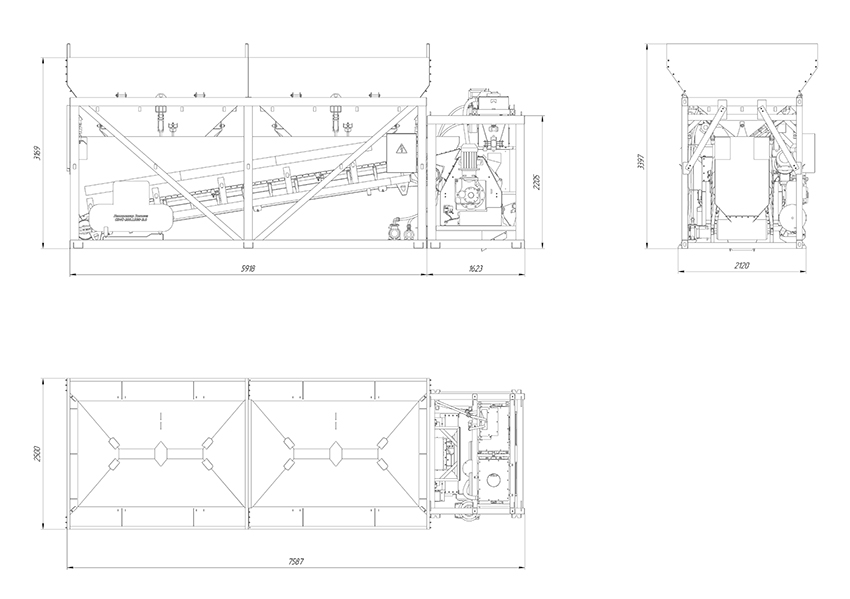

Concrete plant SMART-20 0.0-16 (2x8)

26 427 184 ₸

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| BP-1G-500 single-shaft concrete mixer |

| Mounting Frame |

| Dosing complex DKT-16 |

| BD-15 Block of Dispensers |

| Compressor SB4/C-200.LB30-3.0 |

| PAM 4.0 SCADA control panel |

| Set for assembly and connection |

| Screw conveyor ⌀168/4,000 |

| Twin-shaft concrete mixer BP-2G-375 |

| Planetary counter-current concrete mixer BPP-3V-375 |

| Rastarivatel big bags with el. URM hoist (s) |

| Rastarivatelʹ big-beg cement RMK-2M |

| STs-42 Cement Silo |

| Pumped Calpeda NM 40/12 F / A |

| Aeration system silo SC |

| Safety valve XD-YF250A with a setting ring |

| Emergency pressure relief valve PV273 |

| Cement level sensor G2 1/2 220V |

| Butterfly valve DN300 with manual drive |

| Vibrator MVE 300/3 |

| Cement silo filter with vibration cleaning FCS-14 |

| RMK-2MP cement big bag grinder is designed for grinding cement big bag bags |

| Cement filter with pneumatic cleaning AIRFILL25 |

On-site мобильный бетонный завод SMART-20 0.0-16 (2х8), capacity 20 m3 concrete per hour of work.

The plant is supplied already fully ready for use, does not require any makeready, checkout or foundation construction.

Installed in an open area, on any dense surface without preparation, or in any room with a ceiling height of at least 4 meters.

Start-up: connection to 380 V voltage supply and water feed. It takes less than two hours!

The principle of automatic operation:

- Инертные (песок, отсев, щебень и прочее), которые будут использоваться в производстве бетонараствора, распределяются по отсекам бункера инертных по наименованию. Количество бункеров равняется 2 шт. Таким же образом, распределяются по классу цемент в силосе, вода и добавочные вещества в расходные баки.

- After selection of a particular concrete formula, there needed to input the required volume (m3). After this the process of production starts.

- Inert materials are batched separately according to set weight. The batching is performed on the belt conveyor on which they are fed by opening of the hopper's gate.

- Batched inert materials are loaded into the mixer on this weigh belt conveyor.

- Cement, water and various chemical additives are fed to the corresponding dispensers where they are weighted according to the formula specified in the automation system.

- After dosing of all components of the concrete turns the solution through a metering valve fed into the mixer.

- The mixture of all components in the mixer is stirred for a certain time and a concrete solution is supplied through the drain valve mixer.

BP-1G-500 single-shaft concrete mixer

Volume 500 liters. Positive concrete mixer with one horizontal shaft. 6 paddles for mixing. 11 kW drive. Rotation speed - 30 rot/min.

6 mm thick paddles made of wear-resistant cast iron, adjustable for gap aligning.

The armor is also made of wear-resistant cast iron 10 mm thick, replaceable, bolted. Warranty period until wear is at least 2 years or 40,000 cubic meters of concrete.

Unloading is carried out through a pneumatic gate

0.33 m is produced in one cycle3 concrete. The cycle lasts less than a minute. Thus 1m3 бетона производится за три минуты работы установки SMART-20 0.0-16 (2х8).

Dosing complex DKT-16

It has a large capacity 16 m3 inert materials. These are two bunkers with a volume of 8 cubic.

Large loading width of the bunkers – 2,9 m

Not a high loading height 3,17 meters, does not require the manufacture of an additional ramp.

The conveyor is equipped with a smooth belt and a lined drum.

Weighing conveyor, on suspended strain gauges. Dosage error 1%. Conveyor drive power 7.5 kvt.

The hoppers are equipped with two pneumatic shutters and one vibrator and shaker.

BD-15 Block of Dispensers

It consists of three components: a cement dispenser, a water dispenser and a chemical additive dispenser.

The batcher of cement on 150 kg is supplied with the pneumatic gate, and the vibrator shaker. The weight dispenser is located on three load cells.

Weighing water dispenser for 75 liters, with three high-precision strain gauges.

Chemical dispenser made of stainless steel. The batcher of chemistry and water are supplied with the pneumatic valve for discharge of liquid.

The armored elements of the concrete mixer body are made of

Consists of a piston compressor and a pneumatic system. Capacity 500 liters per minute, power 3 kW. Pressure 11 atm. The compressor is already built into the frame.

PAM remote control

Work on the principle of pressing one button, select the brand of concrete - the amount of concrete and press the start of the cycle! Controller and touch graphic control panel.

Capacity 20 m3/hour of ready-mixed concrete (in case of continuous operation, with formulas with 2 aggregates and 1 binding agent(its maximum weight - 300 kg per 1 m3 of concrete), in case of normal flow characteristics, 5% sand moisture, 0.5 water/cement proportion, 30 seconds mixing time and above-zero temperature.

Discharge of ready mix into a bucket.

- Capacity 20 cu m per hour

- Ultra-mobile RBU, transportation in the first 20 foot container or a 5 ton truck

- Installed directly on site where the concrete is needed

- No foundation or skip pit needed

- Quick deployment and start-up - within 1 hour

- Software on its own SCADA system: accounting for the consumption of materials and equipment operation, remote access and control over the work

- 2 year full warranty

Technical Features

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning team

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

Mr. Astana, prospekt Akzhol, building 44, of. 32

e-mail: sales@zzbo.ru

Artem Kononovich

Director of the branch in Kazakhstan

Phone: +7 (7172) 760-141

e-mail: sales@zzbo.kz

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions