Planetary concrete mixer

counter-current BPP-3B-375s

15 213 990 ₸

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| Бетоносмеситель планетарный противоточный БПП-3В-375с |

| Mixer drive planetary 11 kW |

| Concrete unloading gate. Drive - hydraulic cylinder |

| Hydro station |

| Replaceable scaly-type armor. Material: steel |

| Mixer cover with viewing window |

| Secure access system |

| Spokes reinforced |

| Changeable blades. Material: ЧХ16Н2Т cast iron (chromic high alloy wear-resistant) |

| Electricity to connect the remote control |

| Water treatment system with water spray nozzles |

| Concrete mixer machinery certificate |

| Control panel |

| Set of spare parts (paddles, armour, spokes) |

| Batching complex |

| Support for mixer |

| Cement Silo |

| RB-2 Big-bag discharger |

| Screw conveyor |

Planetary counter-flow concrete mixer BPP-3V-375 is a forced concrete mixer, the working bodies of which make a complex movement in a dish-shaped container.

The principle of mixing in the planetary concrete mixer BPP-2V-375

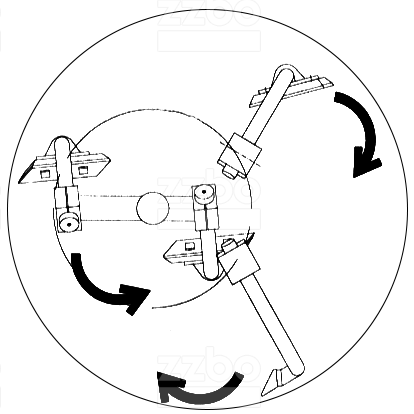

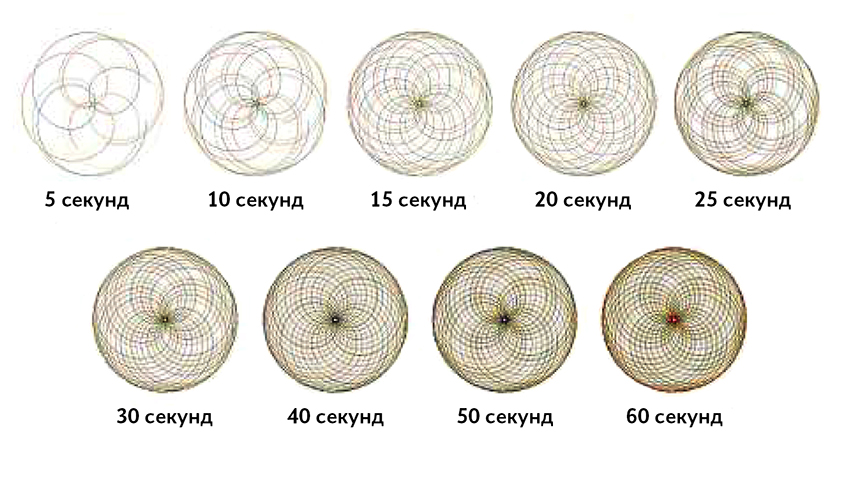

Mixing shafts and blades rotate around the concrete mixer vertical shaft and about its axis at the same time.

The blades move along complex circular trajectories, which causes the components of the mixture to collide in oncoming flows. This makes it possible to obtain good homogeneity when mixing small volumes of finely dispersed components into the main volume of the mixture (for example, when adding dyes).

Water in planetary mixers, in the production of ultra-rigid concrete mixtures, is usually supplied under pressure through a sprayer, which ensures uniform wetting of the super-rigid mixture throughout the batch.

However, in the production of ultra-rigid concrete mixtures, which include components having different bulk densities, planetary mixers will perform worse than twin-shaft concrete mixers. This is due to the fact that the blades move in a horizontal plane, which leads to the separation of such a mixture. Light and large particles "float" under the influence of gravity, which is clearly visible in the production of super-rigid mixtures on expanded clay, sawdust, mixtures for fiber-reinforced concrete and polystyrene concrete. For the production of such mixtures, it is recommended to use twin-shaft concrete mixers.

Mixing takes place with double circular motions of the blades, the blades cover the entire bottom of the mixer in 12 seconds.

CAMOZZI pneumatic gate - two-side

Planetary concrete mixer BPP-3V-375 intended for the preparation of semi-dry mixtures used for vibrocompression and mortars.

Recommended for preparing super-hard concrete mixes!

Planetary compulsory concrete mixer BPP-3V-375 loading volume 375 liters, ready concrete output 250 liters.

Concrete mixer is equipped with a one prison with management hydraulic cylinder. An oil station is used to control the hydraulic seal, it is included in the basic package.

The armored elements of the concrete mixer body are made of become hardness HRC58… 60.

Concrete mixer blades are made of wear resistant cast iron hardness HRC60… 62.

В корпусе для контроля за производством бетонной смеси имеется два смотровых люка, которые оснащены средствами безопасности в виде концевых выключателей.

Power mixer drive 11 Kw, planetary reducer.

To improve the quality and speed of mixing, the concrete mixer is equipped with a water supply system with water spray through special nozzles.

. An oil station is used to control the hydraulic seal, it is included in the basic package.

- mixtures for fiber-reinforced concrete and polysterol concrete. For the production of such mixtures, it is recommended to use twin-shaft concrete mixers.

- mixtures for fiber-reinforced concrete and polysterol concrete. For the production of such mixtures, it is recommended to use twin-shaft concrete mixers.

- mixtures for fiber-reinforced concrete and polysterol concrete. For the production of such mixtures, it is recommended to use twin-shaft concrete mixers.

- mixtures for fiber-reinforced concrete and polysterol concrete. For the production of such mixtures, it is recommended to use twin-shaft concrete mixers.

. An oil station is used to control the hydraulic seal, it is included in the basic package.

- gravitational separation of mixture components having different bulk mass

- significant mixer unloading time

CAMOZZI pneumatic gate - two-side

- Planetary system for mixing a mixture of 375 liters

- Ideal for working with a vibrating press

- System of uniform water spray throughout the entire volume of the concrete mixer

- High-strength wear-resistant cast iron armor and blades

- Powerful 11 kw mixer drive

- 2-year warranty

Technical Features

- Loading volume, l 375

- Ready-mix concrete volume, l 250

- Mixing mechanism drive power, kW 11

- Shutter drive power, kW 2,2

- Total power, kW 17,2

- Number of mixing blades 1x2

- Number of scraper blades 2

- Power Supply, 380

- frequency Hz 50

- Unloading gravitational separation of mixture components having different bulk mass

- Water spray Nozzles

- Planetary frame speed, rpm 14,6

- Planetary shaft speed, rpm 46

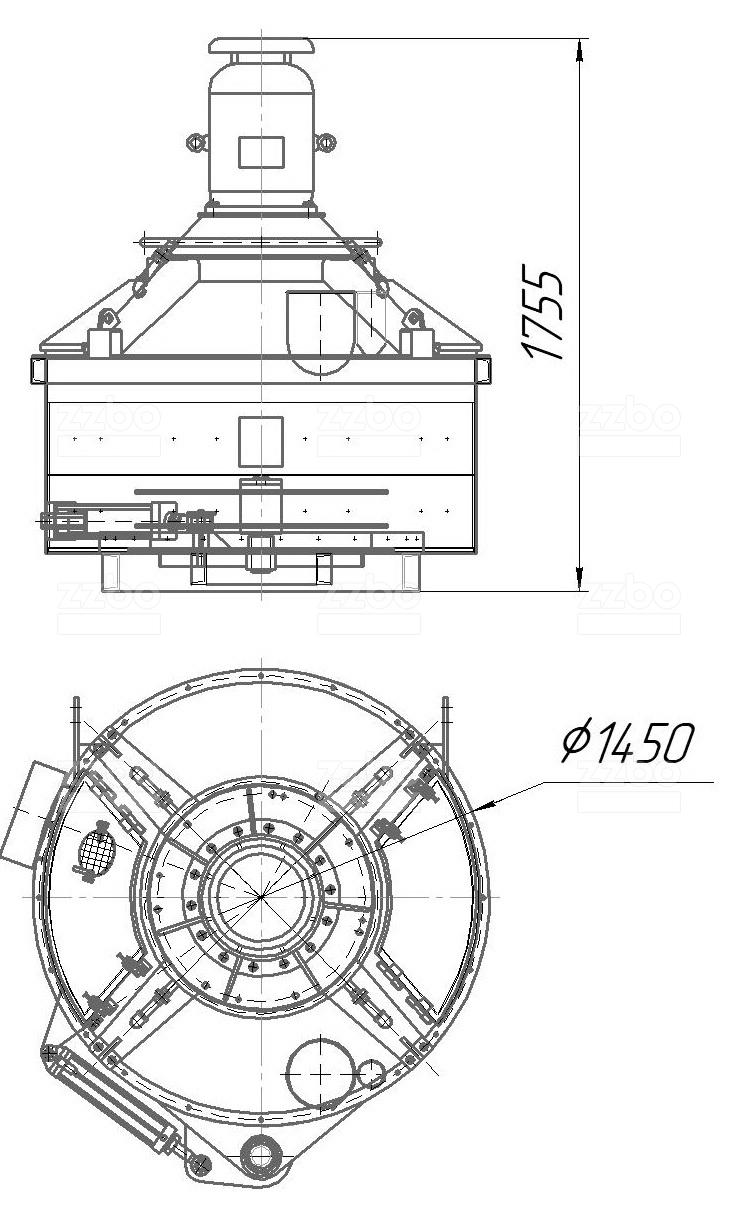

- Width, mm 1557

- Length, mm 1648

- Height, mm 1772

- Weight, kg 1600

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

г. Astana, prospekt Akžol, Zdanie 44, of. 32

e-mail: sales@zzbo.ru

Artem Kononovich

Director of the branch in Kazakhstan

Phone: +7 (7172) 760-141

e-mail: sales@zzbo.kz

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions