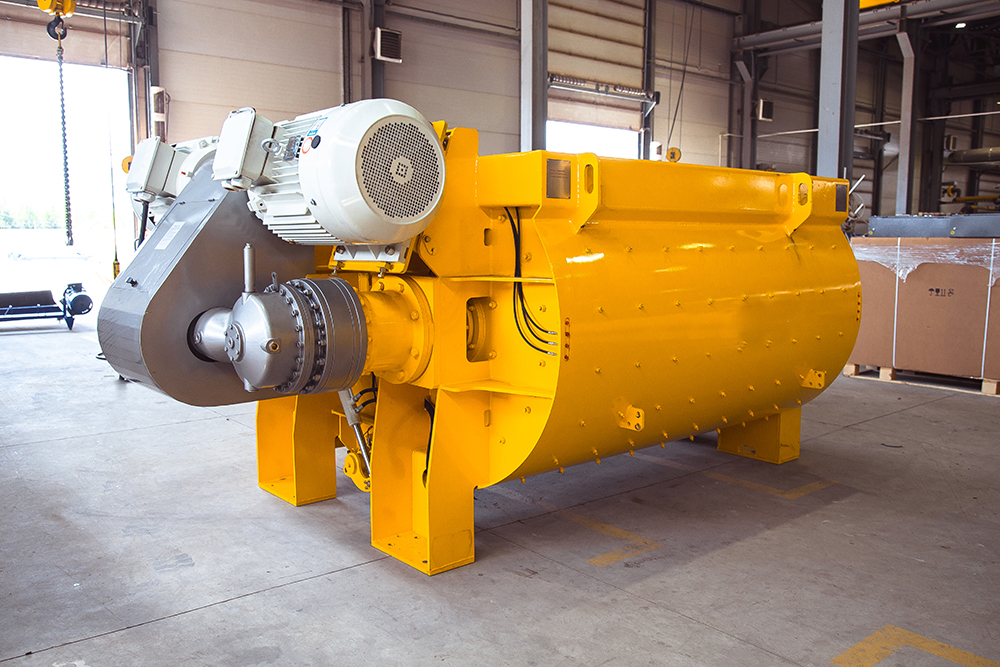

Twin-shaft concrete mixer BP-2G-4500

33 790 680 ₸

26 296 667 ₸

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| Twin-shaft concrete mixer BP-2G-4500 |

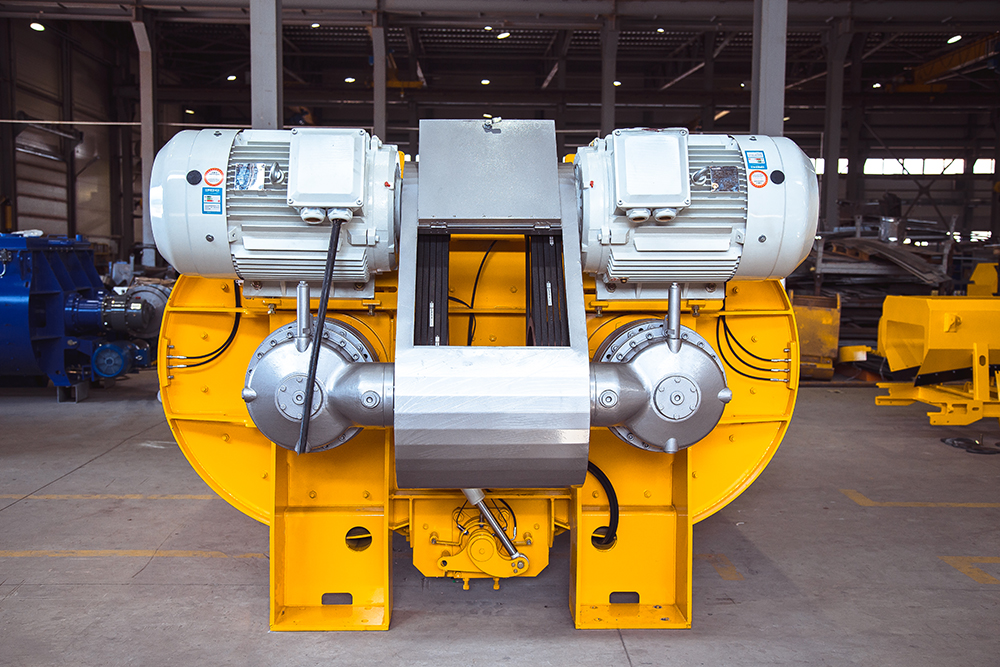

| Planetary gear motors, drive power 55 kW - 2 pcs. |

| gravitational separation of mixture components having different bulk mass |

| 4 kW hydro power plant |

| The number of shafts 2, the number of spokes 2 x 8 |

| The blades are replaceable 16 pieces. Material: Cast iron CHH16N2T (highly doped chromium wear-resistant) |

| Changeable armor flake type. Material: Cast iron ЧХ16Н2 |

| Automatic central lubrication system |

| Secure access system |

| Electricity to connect the remote control |

| Concrete mixer machinery certificate |

| Concrete mixer nozzle ZG 1/4 P159 (stainless steel) |

| Control panel |

| Set of spare parts (paddles, armour, spokes) |

| Compressor Pole Position L25P |

| Compressor SB4/S-50.V47A |

| Batching complex |

| Support for mixer |

| Cement Silo |

| RB-2 Big-bag discharger |

| Screw conveyor |

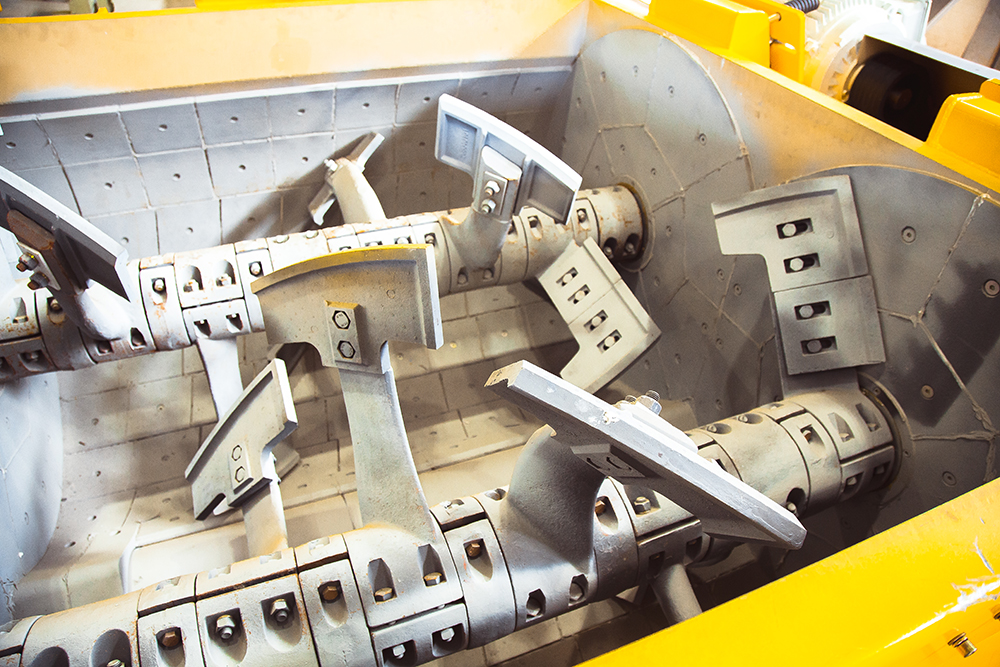

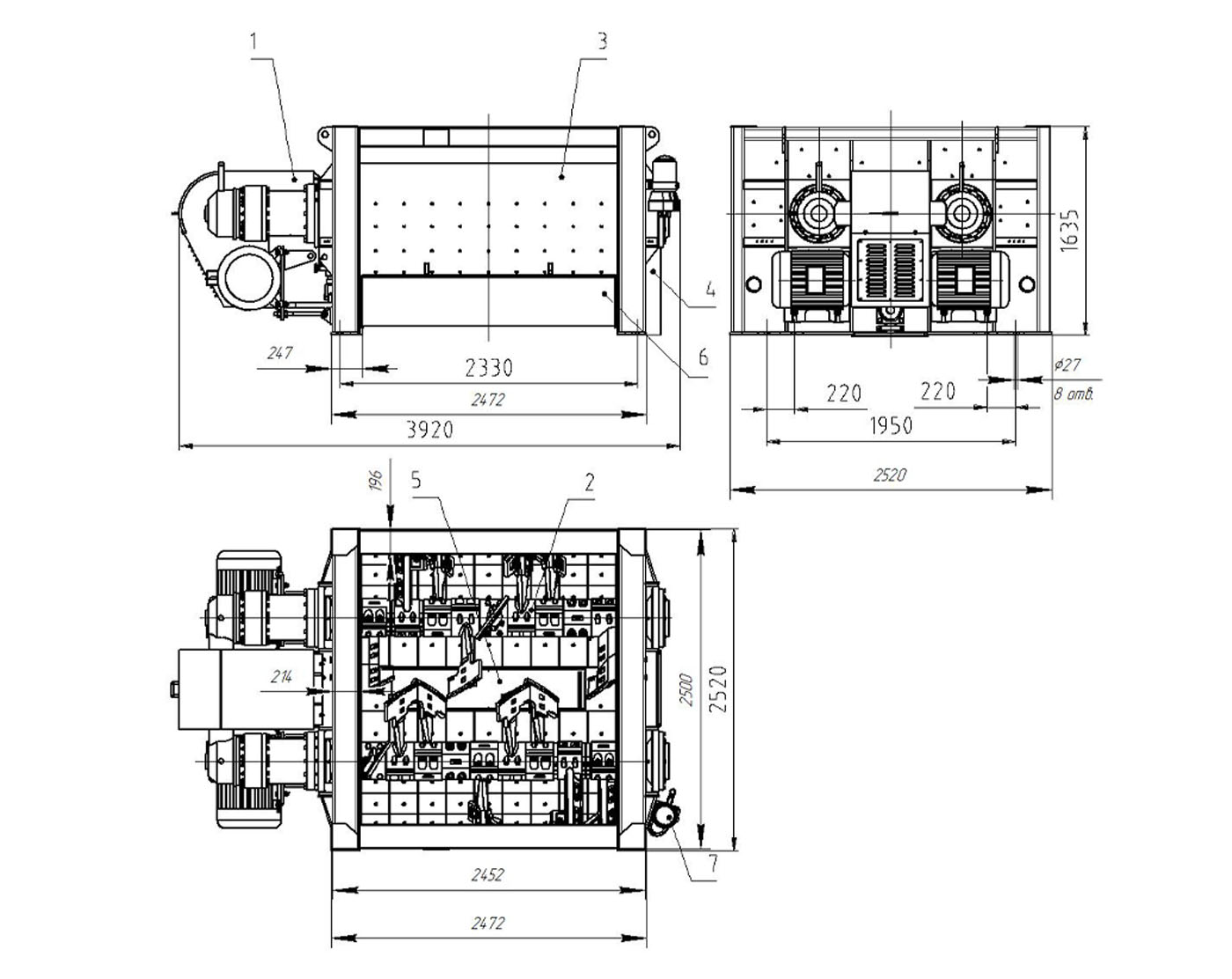

Twin-shaft concrete mixer 4 500 liters It consists of a stationary housing, inside which there are two horizontal shafts с закреплёнными на них лопатками и скребковыми лопастями. Валы соединены между собой валом-синхронизатором для защиты привода. Загрузка компонентов бетонной смеси осуществляется непосредственно в корпус бетоносмесителя, для защиты от попадания посторонних предметов предусмотрена защитная решетка.

Is driven by two electric motors 55 each kW each (110 kW total power) across remennuyu peredachu "Optibelt"Equipped with a jacket and two reinforced planetary gear unit "Just Drive ". mixing shaft rotation speed 25 revolutions per minuteMixer box is coated from the inside by wear-resistant armor, flake type. . The armor is replaceable, fastened with screws. The scaly type armor, consisting of elements, allows you to change only the worn part of the armor, which facilitates repair and maintenance. The unloading of the finished concrete mixture from the twin-shaft concrete mixer is carried out through a window in the bottom of the body, which is closed by a sectoral hydraulic seal. A 4 kW hydrostation comes as standard.

Concrete mixer is equipped with a automatic central lubrication system bearing units and spray water system.

When producing a semi-dry mix for a vibrating press, we recommend installing a ZG 1/4 nozzle for spraying water

- Productivity up to 216 m³ hour

- Two mixing shaft, 2x8 = 16 blades

- Hydraulic seal and hydraulic station as standard

- Reinforced planetary gearboxes, 2x55 kW

- Automatic lubrication system

Technical Features

- Loading volume, l 4,500

- Ready-mix concrete volume, l 3,000

- Mortar volume, l 3,600

- Capacity, cu m 120...216

- The number of cycles per hour, when used in automatic lines 80

- Mixing time, seconds 30...60

- Aggregate size, mm max 80...100

- Shaft rotation speed, rot/min 25

- Supply voltage, V/Hz 380/50

- Total installed power, kW 2x55

- Sector gate, hydraulically operated

- Weight, kg 8,900

- Height, mm 1792

- Width, mm 2485

- Length, mm 3860

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning team

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

Mr. Astana, prospekt Akzhol, building 44, of. 32

e-mail: sales@zzbo.ru

Artem Kononovich

Director of the branch in Kazakhstan

Phone: +7 (7172) 760-141

e-mail: sales@zzbo.kz

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions