Concrete plant FLAGMAN-216

220 982 271 ₸

212 420 543 ₸

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

| Twin-shaft concrete mixer BP-2G-4500 (finished concrete 3 m³) |

| Overpass E4-216L |

| Storage hopper 3 m³ |

| Dosing block BD-180 (cement 1800 kg, water 1000 kg and chemical additive 50 kg) |

| Platform with ladders, for the installation of a DB and a storage bin |

| ABAC Pole Position L20P Compressor (Italy) |

| Belt conveyor LK-1.0-30 |

| Dosing complex DKM-120 (4х30 m³) |

| Control panel PA-3.0 SCADA-5.0 (144..216) with monoblock |

| Enlarged Operator Cab (luxury version) |

| Модульная сэндвич-обшивка |

| Комплект крышек бункеров с автоматическим приводом |

| Регистры обогрева бункеров |

| Set for CBP assembly and connection |

| Auger for cement ⌀32312000 |

| Auger for cement ⌀27315000 |

| Cement silos to choose from |

| Binding for cement silos |

| Pump Calpeda MXH 202E |

| Water loading pump |

| Steam generator PG-2000 on the shoulder |

| Парогенератор ПГ-2000 в блок-контейнере |

| Water heating tank BVG-25 |

| Heat generator TGV-600 for heating |

| Теплогенератор ТГВ-600 для отопления в блок-контейнере |

| Hot water boiler KVA-1.5 Gn/LZh |

| Hot water boiler KVA-2.0 Gn/LZh |

Зимний (всесезонный) бетонный завод FLAGMAN-216 работает в автоматическом режиме по принципу «одна кнопка».

The operator only needs to select the brand of concrete (from M50 to M500) and its quantity to be loaded, and press the “start cycle” button, then all that remains is to visually monitor the automatic operation of the plant.

Design of concrete plant - all-weather.

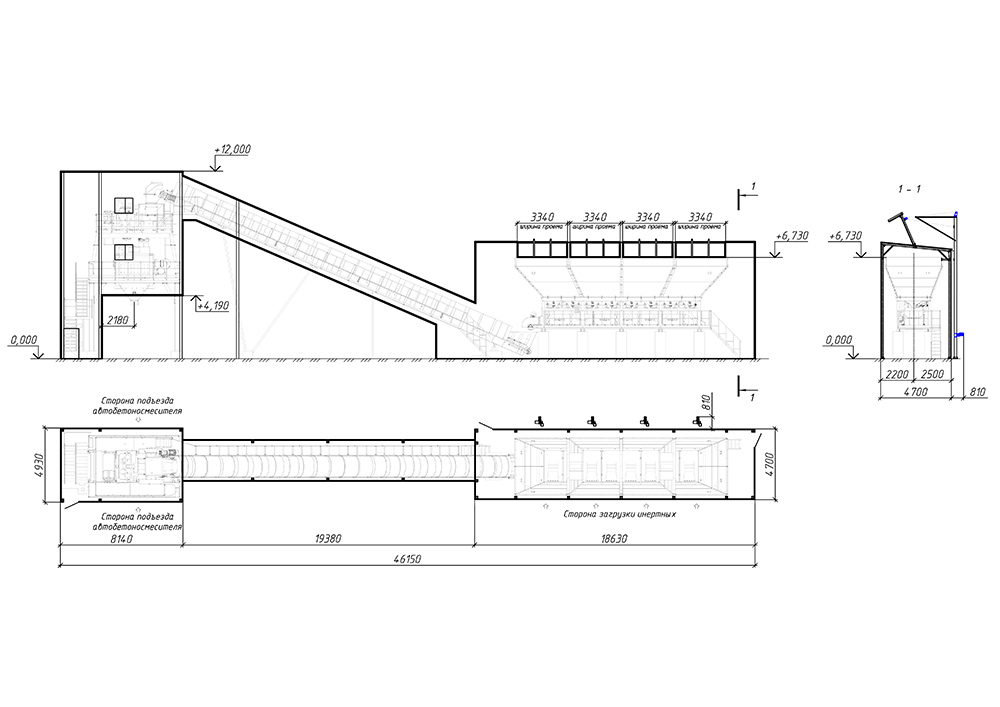

Twin-shaft concrete mixer BP-2G-4500 installed on a flyover, at a height of unloading the finished mixture of 4.2 meters. Concrete mixer volume for loading 4500 liters.

Concrete mixer equipped storage hopper with a volume of 3 m³ for preliminary storage of inert materials coming from the dosing complex.

Based automation system 2x55 kW. Based automation system 2.2 kW.

Concrete mixer equipped with automatic lubrication system.

ZZBO is the official dealer of SICOMA concrete mixers in Russia and the CIS!

It is possible to supply a concrete plant with a concrete mixer from the manufacturer SICOMA.

Dosing complex DKM-120 (4 x30) – предназначен для хранения и точного дозирования инертных.

Inert are loaded and stored in bunkers, number of bunkers 4 x 30 m³ each, total volume of bunkers 120 m³.

Under the bunkers there is a belt conveyor-dispenser with a belt width of 1000 mm and a length of 11 100 mm, on which the exact dosing of the components takes place, the components are fed from the bunkers by opening the slide gates, the gates are controlled пневмосистемой. The number of dampers is 8 pieces. Suspended dosing conveyor on 4 strain gauges of 2 tons load capacity each. Dosing conveyor drive power 18.5 kW.

Dosing complex DKM-120 corrugated sheet with a thickness of 5 ... 6 mm.

Для побуждения схода песка, бункеры оборудованы вибраторами.

Suspended dosing conveyor 3 m³.

When the required dose of inert is collected, the DKM belt conveyor is turned on and the dosed components are fed to the main belt conveyor.

For maintenance of DKM-120 there is a platform with ladders.

Dosing complex DKM-120 length 30,000 mm. Chevron tape 1000 mm wide, tape thickness 10 mm, 4 layers.

Suspended dosing conveyor 30 kW. Drums 320 mm lined.

Equipped with a canopy from precipitation and a special ladder for maintenance.

The mixture rises along the conveyor and enters the storage hopper of the concrete mixer with a volume of 3 m³.

Storage hopper 3 m³. Wall thickness 5mm. Gate unloading control - pneumatic cylinder. A vibrator is installed to induce the exit. The inside of the bunker is covered armor 10 mm Hardox steel.

Based automation system consists of a cement dispenser for 1800 kg. The cement dispenser is equipped with 3 strain gauges of 1000 kg each and a vibrator to stimulate the cement flow.

The water dispenser for 1000 liters is equipped with 3 strain gauges of 1000 kg each.

Chemical dispenser additives per 50 liters on a 100 kg load cell.

Elevated structure serves as the installation of batchers, a storage hopper and a twin-shaft concrete mixer. It has two levels of service with ladders. Concrete unloading height 4 200 mm.

Based automation system для работы пневмосистемы завода с ресивером на 500 литров и производительностью 1210 лмин.

Based automation system cement silos. The volume of silo for this plant is recommended from 100 tons. Silos for cement must be selected the rate of two daily stock performance. For feeding cement from a cement silo dispenser must acquire the correct length screw.

cement silos cement silos (recommended screw diameter 273 mm and length 15,000 m - not included in the basic equipment of the plant).

Cement silos, silo piping and augers are always in stock in Zlatoust!

One cycle lasts for 60 seconds maximum 3 m³ ready concrete or solution, the cycle lasts about 50…90 seconds. Plant capacity 100…216 m³ ready-made concrete or mortar per hour of work.

- Twin-shaft concrete mixer 4.5 cubic meters meters with belt feed, output 3 cu. meters

- Preliminary hopper for inert materials

- Dosing system (cement, water, chemicals) located on a separate platform

- Bunker 4 pieces of 30 cu. meters

- Installed in a place where concrete is needed, does not require foundation preparation SCADA system complete with a monoblock: accounting for the consumption of materials and equipment operation, remote access and control over the work

- Transportation in 4 euro trucks to the installation site

- Full warranty 2 years

- High efficiency

- All year round operation, at any temperatures

- No need for a separate workshop and premises

Technical Features

- Productivity, m³ hour 110...216

- mode auto

- Two-shaft concrete mixer BP-2G-4500 4500 liters for loading

- Hoppers (number x volume m³) 4 x 30

- Silo capacity (optional), tons 160...2060

- Design winter

- Load of inert materials into the concrete mixer belt conveyor

- Total power, kW 165

- Weight, kg 83000

- Height, mm 12000

- Width, mm 4,700

- Length, mm 46150

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods

Call hotline in Kazakhstan

Our managers will answer all your questions from Monday till Friday:

from 06:00 a.m. to 05:00 p.m. (GMT+3, Moscow time)

Address: 010000, Kazakhstan, Akmola region,

г. Astana, prospekt Akžol, Zdanie 44, of. 32

e-mail: sales@zzbo.ru

Artem Kononovich

Director of the branch in Kazakhstan

Phone: +7 (7172) 760-141

e-mail: sales@zzbo.kz

Place your order

We will send you the price,

conditions and terms of delivery

Response within 1 hour

You will get the offer with

individual delivery and payment conditions